China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel in the elevator engineering application because of its fire, heat preservation, sound insulation, shockproof, strong load-bearing, buffer resistance, light weight and other advantages, is the most ideal material for public elevators and freight elevators, greatly reducing the load of the elevator.

Read more

The performance of aluminum honeycomb panel decorative panel material generally choose 3003, 5005 and other brands, low alloy composition of the 1100 plate less used. Decorative finish in the form of spray or roller coating with polyester or fluorocarbon paint

Read more

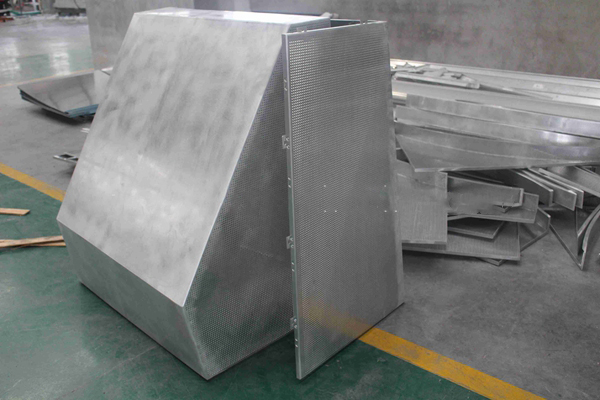

The aluminum honeycomb panel adopts a composite honeycomb structure, which is formed by hot pressing of preformed box-shaped face plate and back plate and aluminum alloy honeycomb core material. Select high quality 3003H24 alloy aluminum plate 5052AH14 high manganese alloy aluminum plate as the substrate

Read more

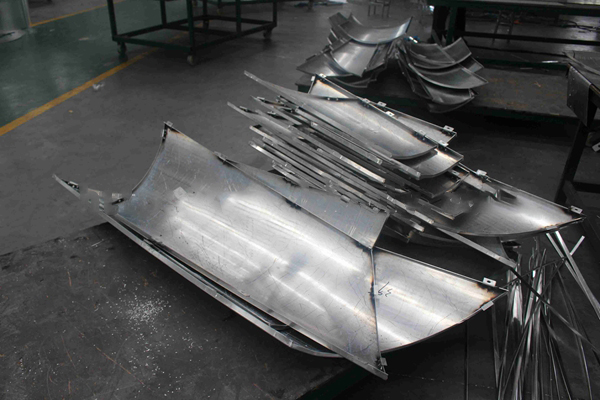

Aluminum honeycomb panels were originally used in the aviation manufacturing industry. They are widely used in elevator decoration engineering, rail transit vehicle decoration, ship interiors, building curtain walls, electronic whiteboards, stadiums, bus shelters and many other industries.

Read more

The core layer of the honeycomb aluminum plate is a typical porous structure, and the continuous polygonal cells are regularly arranged, so the cross-sectional area of the solid part of the honeycomb plate is very small, so its density is relatively small compared to other sandwich materials.

Read more

In addition to the protection of materials entering the site and finished Products, as well as semi-finished Products and auxiliary accessories, for semi-finished materials and finished Products that have been installed or stacked on each floor.

Read more