China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

In the aluminum honeycomb panel production composite process, according to the existing text data, drawings for sheet metal processing and aluminum honeycomb panel processing composite refinement design, there are the following steps:

Read more

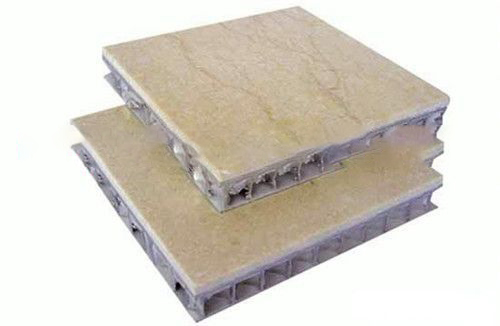

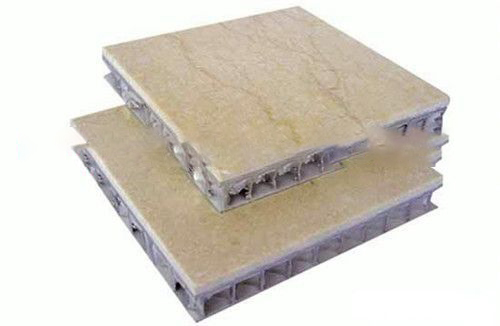

Stone honeycomb aluminum plate is generally 3-5mm stone, 10-25mm aluminum honeycomb plate, through a special adhesive bonding compound.

Read more

For the modern furniture industry, which has strict environmental protection requirements, using aluminum honeycomb panels to make furniture processing materials is a good material choice in the new century,

Read more

The size and shape of the incision shall be determined according to the assembly requirements. The inner surface of the outer aluminum plate of the honeycomb aluminum plate shall not be scratched when the aluminum core is cut off. The aluminum core of 0.3~0.5mm shall be reserved on the outer aluminum plate of each part;

Read more

Wood grain aluminum honeycomb panel: aviation technology is applied to civil construction, vehicle and ship decoration. It is the application of aviation and aerospace materials in the field of civil construction.

Read more

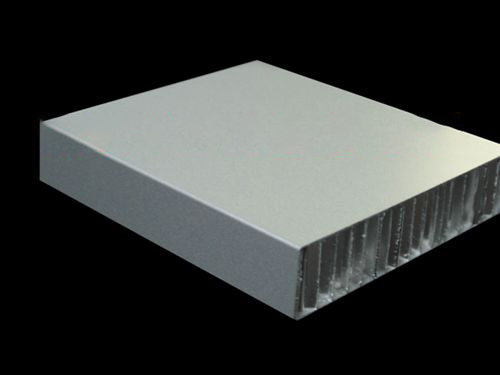

Aluminum corrugated composite board is a new type of composite aluminum curtain wall material made of corrugated aluminum board with 0.6-0.8mm bottom plate, 0.4mm middle 0.2mm corrugated aluminum board, coated with thermosetting epoxy resin adhesive on the surface of corrugated core material, and compounded by heating and pressing. Its compounding method is similar to that of corrugated cardboard box board.

Read more