China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

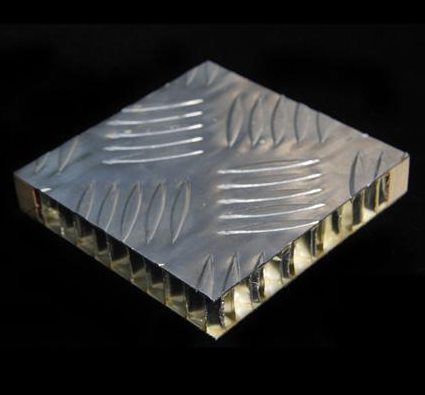

Aluminum honeycomb panel peel strength factors using polyurethane, epoxy resin room temperature curing adhesive production of aluminum honeycomb panel, the bonding strength is low, for the honeycomb core side length of 4mm, panel thickness of 1mm, the total thickness of 10mm aluminum honeycomb panel measured 180 ° peel strength is about 4N/mm.

Read more

The resistance of the aluminum honeycomb panel structure is inspired by the honeycomb. The resistance of the aluminum honeycomb panel structure to the extrusion force is much higher than any round or square. The aluminum honeycomb panel honeycomb structure material began to be available.

Read more

For the installation of honeycomb aluminum plate, tear off the folding part of the protective film of honeycomb aluminum plate, and stick the masking paper at the folding part of 90 ° corner.

Read more

Some knowledge of aluminum honeycomb panel, aluminum honeycomb panel is suitable for civil construction, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction.

Read more

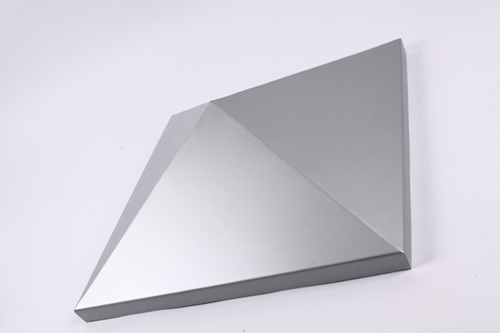

In the heterosexual aluminum veneer processing industry, in addition to conventional aluminum veneer, there is a special category, which is shaped aluminum veneer, so what aluminum veneer belongs to shaped aluminum veneer??

Read more

The aluminum veneer adopts high-quality aluminum alloy panel as the base material, and the leading numerical control bending skills ensure that the plate can be flat and not deformed after processing. In the process of the device, the external force resistance is superior, the appearance color is uniform, the ultraviolet radiation resistance, the oxidation resistance and the super corrosion resistance are excellent.

Read more