China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

在aluminum honeycomb panel productionIn the composite process, according to the existing text data, drawings for sheet metal processing and aluminum honeycomb panel processing composite refinement design, there are the following steps:

A. change all irregular hand drawings to auto Cad drawing, after confirmation, print three copies and bind them into a book according to batch and drawing number. One copy of technology (transferred to archives after completion), one copy of workshop and one copy of quality assurance inspection.

b.对没有进行aluminum honeycomb panel板块编号的图纸,要统一编号。对已编号的图号进一步编号:后缀+a代表面板;后缀+b代表底板;后缀+c代表铝蜂窝芯;依次类推。

c. For the aluminum plate or other material surface bottom plate that needs sheet metal processing, the bending coefficient should be carefully measured and documented.

d. Write a catalog, calculate the area of a single piece and the total area, etc.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

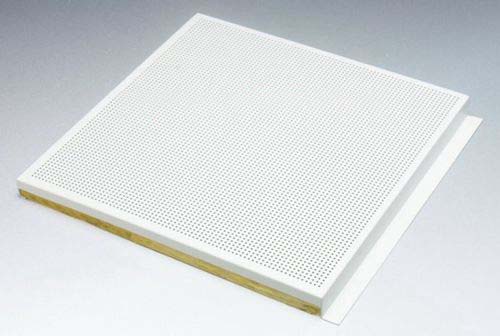

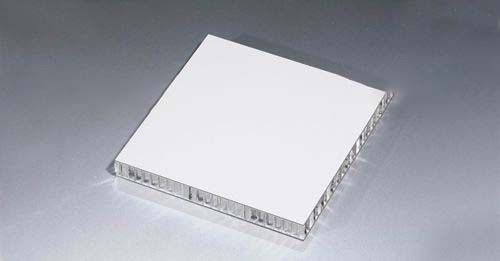

Aluminum honeycomb panel, suitable for civil construction, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction. The whole processing process of aluminum honeycomb panel production is completed in a modern factory. Hot pressing technology is adopted. Due to the high heat conduction value between aluminum skin and honeycomb, the thermal expansion and cold contraction of inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely. The slidable installation buckle system will not cause structural deformation during thermal expansion and cold contraction.

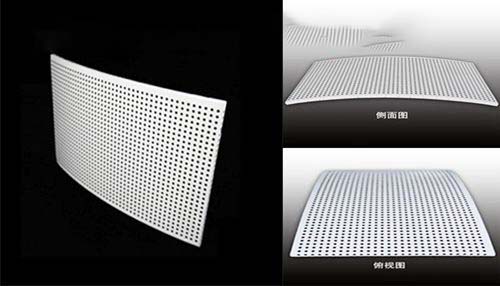

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Aluminum honeycomb panel curtain wall with its light weight, high strength, stiffness and many other advantages, has been widely used in high-rise building exterior decoration. The total thickness of aluminum honeycomb panel production is 15mm, and the aluminum honeycomb panel with 1.0mm thickness is only 6Khg/㎡.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

The weight of honeycomb panel with the same rigidity is only 1/5 of that of aluminum veneer and 1/10 of that of steel plate. The interconnected aluminum honeycomb cores are like countless I-beams. The core layers are distributed and fixed in the whole plate surface to make the plate more stable. Its wind pressure resistance is much higher than that of aluminum veneer and aluminum veneer. It is not easy to deform and has good flatness, even if the cell size of honeycomb panel is large. It can also achieve extremely high flatness and is currently the preferred lightweight material for the construction industry.

Recommended:What are the advantages of corrugated composite aluminum plate