China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

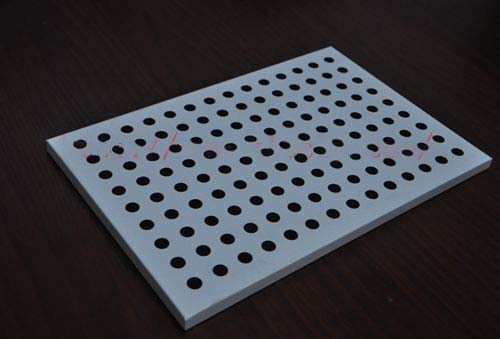

Honeycomb aluminum plate processingThe following provisions shall be met:

1. The size and shape of the incision shall be determined according to the assembly requirements, and the inner surface of the outer aluminum plate of the honeycomb aluminum plate shall not be scratched when the aluminum core is removed. 0.3~0.5mm aluminum core should be retained on the outer aluminum plate of each part;

2. For the processing of right-angle components, the corners should be bent into circular arcs, and the corner seams should be sealed with silicone weather-resistant sealant;

3, the processing of large arc angle components, arc parts should be filled with fireproof materials;

4. For the processing of the edge, the outer aluminum plate should be folded 180 °, and the aluminum core should be encapsulated.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The characteristics of honeycomb aluminum plate processing

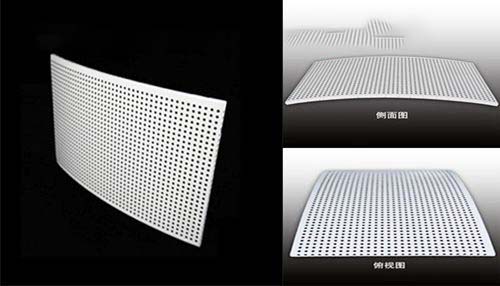

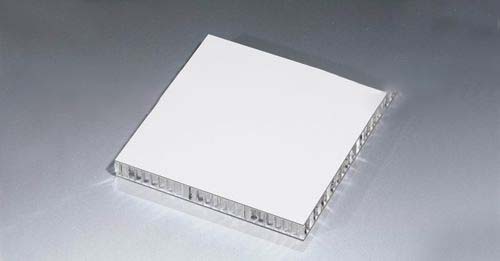

1, large surface, high flatness: without any reinforcement measures, honeycomb aluminum plate surface size can reach 1500*5000mm, and can maintain excellent flatness.

Light weight: the weight of the honeycomb aluminum plate is only 5-5.5KG/square meter, which greatly reduces the load-bearing load of the building.

3, high strength can withstand high strength pressure can shear force, not easy to deformation, can meet the requirements of high-rise building wind pressure.

4. Customized honeycomb aluminum plate can be customized according to customer\'s needs in terms of size, shape, paint surface and color.

5, easy installation can be installed in any order, each wall panel can be removed and replaced separately, improve the flexibility of installation and maintenance, reduce costs.

6. The box-type structure honeycomb aluminum plate is a box-type structure with surrounding edges, which has good tightness and improves the safety and service life of the honeycomb aluminum plate.

7, multi-purpose for building curtain wall, package column, eaves, roof and outdoor ceiling, etc.

Installation and Construction Technology of Honeycomb Aluminum Plate

Construction process flow: setting out → fixing the connecting piece of the framework → fixing the framework → installing the honeycomb panel → closing structure treatment → inspection

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Honeycomb aluminum plate installation construction: measurement and setting out

(1) Due to the large allowable error of civil construction,Honeycomb aluminum plateProcessing engineering construction requires high precision, so it can not completely rely on the civil horizontal baseline, must be re-measured by the reference axis and benchmark, and correction review.

(2) Determine the curtain wall positioning line and grid line position at the bottom according to the design.

(3) Use theodolite or laser verticator to lead the positive and negative angles of the curtain wall, and use the steel wire fixed on the steel bracket as the marking control line.

(4) use level and standard steel tape, etc. to lead out the elevation line of each layer.

1) Determine the center line of each facade.

2) The distribution of measurement errors shall be controlled during measurement, and the errors shall not be accumulated.

3) The measurement and setting-out shall be carried out under the condition that the wind force is not more than level 4, and the wind shelter measures shall be taken.

4) After setting out and positioning, the control line shall be checked regularly to ensure the verticality of the honeycomb aluminum curtain wall and the correct position of the metal mullion.

5) All facade decoration works shall be unified with datum line, and attention shall be paid to construction coordination.

Recommended:What are the advantages of wood grain aluminum honeycomb panels