China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

The use of aluminum honeycomb panel

(1) External wall hanging board of building curtain wall

(2) Interior decoration works

(3) Billboards

(4) Buildings on board

(5) Aviation Manufacturing

(6) Indoor partition and commodity display

(7) Commercial transport vehicle and container vehicle body

(8) Buses, trains, subways and rail transit vehicles

(9) For the modern furniture industry with strict environmental protection requirements, using aluminum honeycomb panels to make furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to use aluminum honeycomb panels without unnecessary environmental protection procedures when processing furniture. In addition, aluminum honeycomb panels can be diversified such as solid wood, aluminum panels, gypsum panels and natural marble stones, all of which can be made into honeycomb panels, material selection is convenient.

(10) aluminum honeycomb panel partition: the emergence of aluminum honeycomb panel partition, breaking the traditional partition mode, with its noble, fresh and stylish style, won the market share of medium and high-end office space.

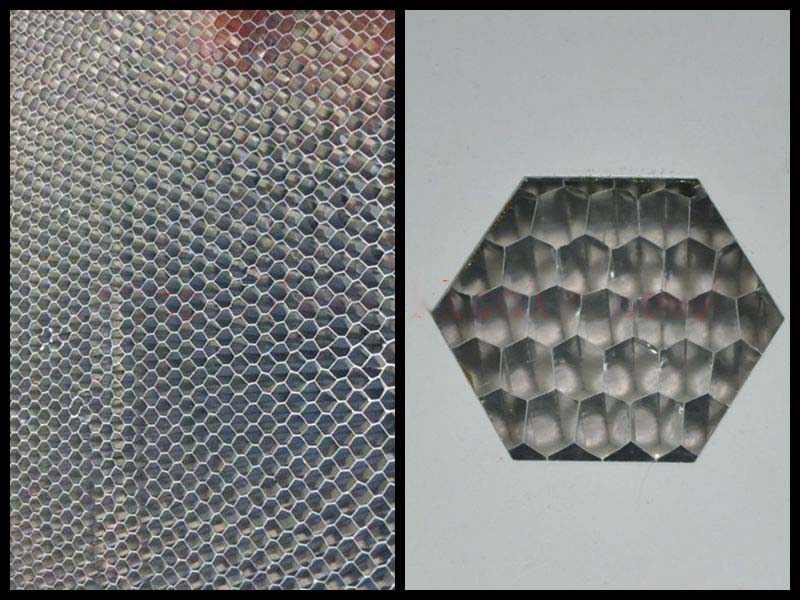

Guangdong aluminum honeycomb panelThe panel is made of high-quality 3003H24 alloy aluminum plate or 5052AH14 high-manganese alloy aluminum plate as the base material. The thickness of the panel is 0.8~1.5mm fluorocarbon roll-coated plate or light-resistant baking varnish. The core material is hexagonal 3003 aluminum honeycomb core. The aluminum foil is formed by roll forming technology to complete the front and back skins. There are small holes in the honeycomb aluminum skin, so that the gas can flow freely, therefore, extremely high flatness can be ensured. The inner layer is a special hexagonal honeycomb, and the use of aluminum honeycomb panel is called \'aluminum honeycomb panel\' because of its honeycomb shape \'.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

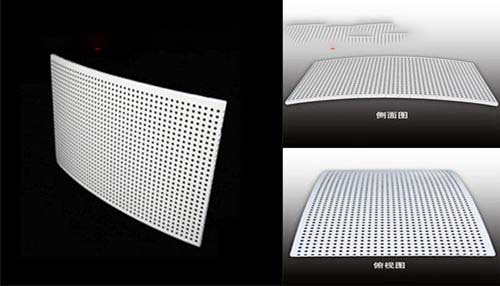

Aluminum honeycomb panels are used in building ceilings, and honeycomb aluminum ceiling systems have been used for a long time. From the panel material, shape, installation system, color and surface treatment of aluminum honeycomb panels, engineers are provided with a wide range of choices, which can be seen from a variety of angles. Show the beauty of aluminum honeycomb panels, with excellent design freedom.

Our company has an advanced honeycomb aluminum panel production line. Through a unique process and strict production system, the aluminum honeycomb composite panel has super peel strength and excellent physical properties, which are completely comparable to aluminum gusset ceiling and aluminum corrugated board ceiling.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Honeycomb aluminum plate is light in weight, good toughness, high strength, good sound insulation and heat insulation performance. The use of aluminum honeycomb plate is an ideal product choice for large-scale projects such as subways or stations, and honeycomb aluminum plate supports on-site temporary processing and diversification of installation methods. It can carry out difficult ceiling design and facilitate maintenance or replacement.

Recommended:What is the scope of application of aluminum corrugated board