China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Corrugated aluminum plate processingUse a level gauge to copy out the horizontal point on the corner of each wall (column) in the room (if the wall is long and the aluminum corrugated board, several points should be appropriately copied in the middle), pop up the level line (the level line is generally 500 ㎜ from the ground), measure from the level line to the design height of the suspended ceiling, and use the powder line to pop up the level line along the wall (column), which is the lower leather line of the suspended ceiling grid.

Use expansion bolts to fix hanging rods. The boom of ф 6 may be used. The hanger bar can be cold drawn steel bar and coiled steel bar, but the coiled steel bar should be straightened by machine.

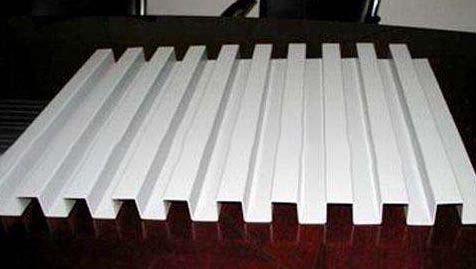

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Corrugated aluminum plate processing吊杆的一端同L30*30*3角码焊接,(角码的孔径应根据吊杆和膨胀螺栓的直径确定)另一端可以用攻丝套出大于100㎜的丝杆,也可以买成品丝杆焊接。制作好的吊杆应做防锈处理,吊杆用膨胀螺栓固定在楼板上,用冲击电锤打孔,孔径应稍大于膨胀螺栓的直径。

The light steel keel shall be hung on the hanger rod (if the suspended ceiling is low, this process can be omitted and the next process can be carried out directly). Generally used 38 light steel keel, spacing 900 ㎜ ~ 1000 ㎜. The light steel keel shall be installed parallel to the long direction of the room, and shall be arched at the same time. The arching height shall be 1/200~1/300 of the room span.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The cantilever section of corrugated aluminum plate processing light steel keel should not be greater than 300 ㎜, otherwise the boom should be added. The main keel shall be extended by butt joint, and the butt joints of adjacent keels shall be staggered. The light steel keel shall be basically leveled after being hung.

The main features are low density, high tensile strength and high elongation. The weight of aluminum-magnesium alloy is lower than other series under the same area. Therefore, it is commonly used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries.

stainless steel honeycomb plateEasy and fast installation.

The processing technology is continuous casting and rolling, which belongs to the hot-rolled corrugated aluminum plate series, so it can be oxidized deep processing. In China, 5 ××× series corrugated aluminum plate is one of the more mature corrugated aluminum plate series.

Recommended:Performance Characteristics of Adhesive for Aluminum Honeycomb Panel