China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Adhesive for aluminum honeycomb panelSuitable for civil construction, vehicle and ship decoration, etc. It is the application of aviation and aerospace materials in the field of civil construction. The whole processing process is completed in a modern factory, using hot pressing technology, because of the high thermal conductivity between the aluminum skin and the honeycomb, the thermal expansion and contraction of the inner and outer aluminum skin are synchronized.

Its main advantages: strong adhesion, high tensile strength, high hardness, good heat resistance, excellent durability, high toughness, fatigue resistance, aging resistance. The main functions of reinforcement, reinforcement, fixation, anchoring, rebar planting, joint filling, perfusion, repair, composite, insulation, sealing, moisture-proof, and shock-proof.

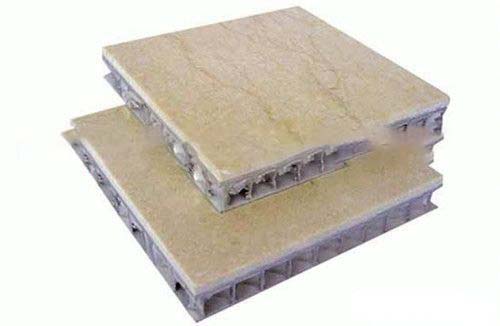

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Aluminum honeycomb panel adhesive paste surface, need to keep clean, no impurities, no water. Apply the prepared glue to the product surface to be pasted (such as aluminum honeycomb plate and marble plate) with a glue scraper, and scrape the glue back and forth, and apply it evenly, so that the glue can fully penetrate and diffuse to achieve full bonding strength.

It has a series of characteristics such as fast heating and curing speed, excellent surface gloss, good insulation, good manufacturability and excellent electrical performance. It is suitable for transformers, rectifiers, AC capacitors, ignition coils, aquarium equipment, stone materials, aluminum honeycomb plates, negative ion generators, high-voltage packages, atomizers and other Products, making electronic components play the role of filling and sealing, insulation protection, moisture-proof and earthquake-proof.

aluminum honeycomb panelThe adhesive strength of honeycomb aluminum plate produced by thermoplastic film continuous composite process is 3-5 times that of honeycomb aluminum plate produced by the first two processes. For honeycomb aluminum plate with regular hexagonal honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm, the measured 180 peel strength value is about 18N/mm. Its adhesion and weather resistance are good, and its peel strength decreases little after 1 year of use.

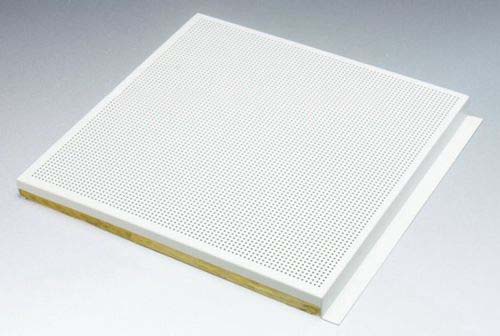

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Its adhesion and weather resistance are good, and its peel strength decreases little after 1 year of use. Because it is continuous production, high efficiency, can meet the short-term mass supply requirements.

Recommended:How about the performance of corrugated alloy aluminum plate