China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

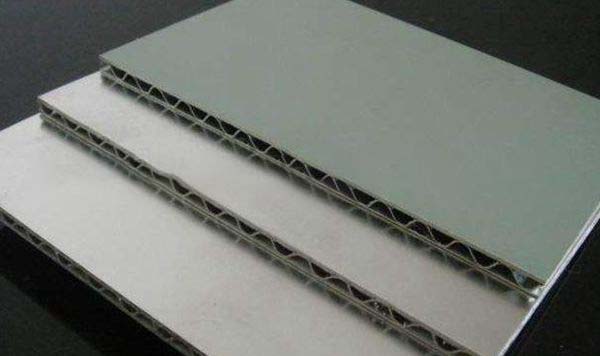

Honeycomb core wood grain aluminum plateIt is a new type of composite material with sandwich structure, which is composed of two layers of aluminum sheet and aluminum honeycomb core through adhesive. The panel of honeycomb aluminum plate is usually sprayed with fluorocarbon coating or polyester coating. The fluorocarbon coating is widely used outdoors because of its good weather resistance and self-cleaning, and the polyester coating is mostly used indoors.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The honeycomb aluminum plate produced by polyurethane and epoxy resin room temperature curing adhesive has low bonding strength. The 180 peel strength measured for honeycomb aluminum plate with honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm.

Honeycomb aluminum plate coating technology

(1) Honeycomb aluminum plate adopts original coating baking technology to ensure the adhesion of the coating and the uniformity and saturation of the color.

(2) The required colors can be provided according to customer requirements, and various special coatings can also be provided.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Honeycomb core wood grain aluminum plate is a series of metal composite panel Products developed by combining the composite honeycomb panel technology of aviation industry. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Honeycomb aluminum plate with high strength alloy aluminum plate as the surface, the bottom plate and aluminum honeycomb core by high temperature and high pressure composite manufacturing, is a kind of composite plate, it uses honeycomb sandwich structure, excellent material selection, advanced technology and reasonable structure, in color, flatness and other aspects have great advantages.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

The bonding strength of honeycomb aluminum plate produced by continuous thermoplastic film composite process is 3-5 times higher than that of honeycomb aluminum plate produced by the first two processes. For honeycomb aluminum plate with regular hexagonal honeycomb core of 4mm in side length, 1mm in panel thickness and 10mm in total thickness, the measured 180 peel strength value is about 18N/mm.

Recommended:Scope of application of aluminized zinc corrugated board