China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

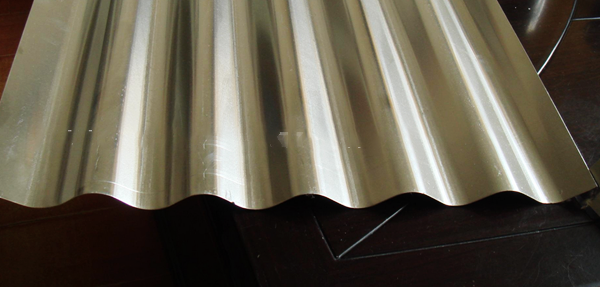

Galvanized zinc corrugated boardIt is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal alloy.

The heat reflectivity of aluminized zinc steel plate is very high, which is twice that of galvanized steel plate. People often use it as a heat insulation material.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Galvanized steel plate is widely used in building materials, home appliances, automobiles, environment, machinery, ships and many other fields of an alloy coating steel plate. The aluminum-zinc plated steel plate is an alloy coated steel plate with aluminum-zinc alloy covering treatment on the surface of the steel plate, which is composed of 55% aluminum, 43.4 zinc and 1.6 silicon solidified at a high temperature of 600 ℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal.

Galvanized zinc corrugated board is a new material in recent years due to high-end applications in China, commonly used CCLI refers. It is a product made of aluminized zinc plate (55% aluminum, 43% zinc and 1.6 silicon) with more corrosion resistance than galvanized steel plate as the substrate, after surface degreasing, phosphating and phosphating, and then coated with organic coating and baked.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Because the steel plate is damp, it will produce oxidation and rust, it must be added to the surface. On the anti-corrosion protection layer, the commonly used anti-corrosion coating is divided into hot-dip galvanized Zn and hot-dip aluminum-zinc alloy Al-Zn (aluminum-zinc alloy composition is 53% aluminum, 43.5 zinc and 1.5 silicon, referred to as 55% Al-Zn). Data show that the comprehensive anti-corrosion ability of 55% aluminum and zinc is 4 times of the same thickness of zinc plating.

stainless steel honeycomb plateEasy and fast installation.

Aluminized zinc corrugated board combines the corrosion resistance and heat resistance of aluminum, as well as the sacrificial anode of zinc, which is a product that perfectly combines the characteristics of aluminized steel sheet and galvanized steel sheet. Made of high-tech aluminum-zinc steel plate, even at 315 ℃ lasting use will not fade, because of its excellent quality is more and more widely used in indoor and outdoor decoration materials, steel structure roof and maintenance system, electrical, electronic, ventilation, machinery manufacturing, drainage system, etc.

Recommended:How about aluminum honeycomb board material