China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Laminate floor buckle stripWear-resistant scratch-resistant, anti-stepping compression: the surface of the reinforced composite floor is covered by aluminum oxide wear-resistant layer, wear-resistant revolutions can reach tens of thousands of revolutions, wear-resistant ability is about 10 to 30 times the ordinary paint floor, which is one of the most significant advantages of reinforced composite floor, it has a strong compressive ability for daily heavy hits.

The pattern of laminate flooring is determined by decorative paper. It can not only be designed into the texture of wood floor, but also can be designed into a variety of patterns, patterns and colors, which can match with various home decoration styles.

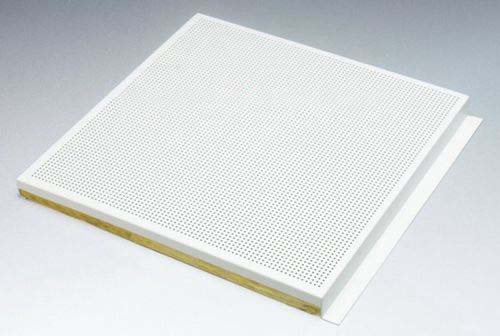

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

the shortcomings of reinforced composite floor buckle:

1, the release of formaldehyde: one of the shortcomings of reinforced composite flooring is the release of formaldehyde, it is necessary to choose the formaldehyde release to reach the national standard reinforced composite flooring brand or product.

2. Most avoid flooding: In particular, it should be pointed out that in the past, dealers once called the reinforced composite floor a\' waterproof floor\'. This is only for the surface. In fact, the reinforced floor is most avoid blisters. Once the water is soaked seriously, its shape is difficult to recover, and if the situation is serious, it may be scrapped.

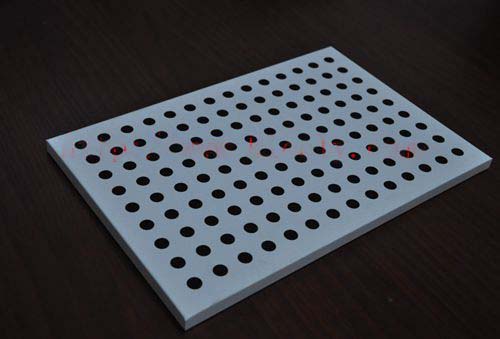

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Maintenance of Laminated Composite Floor Buckle

Often keep the reinforced composite floor dry and clean, if the floor has oil stains and stains, should pay attention to timely removal, can use household soft neutral detergent warm water treatment, the best use of special floor cleaning protection liquid matching with the floor to clean. Do not use alkaline water, soapy water and other corrosive liquid contact with the floor surface, not to use gasoline and other flammable items and other high temperature liquid to wipe the floor.

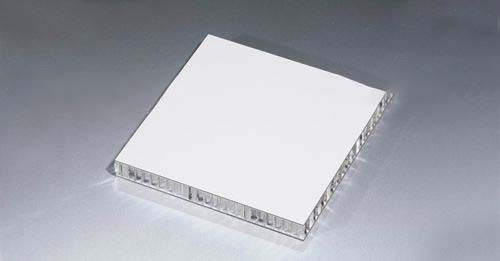

stainless steel honeycomb plateEasy and fast installation.

Under normal circumstances, when the belt conveyor is installed, 2~3 sets of transition groove roller racks shall be installed after the head of the belt conveyor unloads the roller and before the tail of the belt conveyor is changed to the roller to protect the conveyor belt. The ground 2 belt conveyor of Luxi Coal Mine is equipped with 3 sets of transition groove roller racks at the head section, and the groove angles are 30, 25 and 20 respectively. Three sets of transition groove roller racks are also installed at the tail section, the groove angles are 20 °, 25 ° and 30 ° respectively, and the groove angle of the common groove roller rack is 35 °.

Recommended:Development direction of composite honeycomb aluminum plate manufacturers