China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

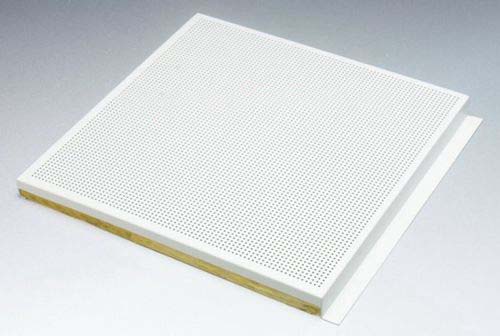

aluminum honeycomb plate aluminum plateIs a combination of aviation industry composite honeycomb panel technology and the development of metal composite panel Products. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

aluminum honeycomb panelIs based on aluminum metal plate, with ordinary aluminum veneer antibacterial, anti-corrosion, long service life characteristics, because of its special design it sound insulation, seismic, moisture-proof effect is also very prominent.

Honeycomb aluminum plate coating technology

(1) Honeycomb aluminum plate adopts original coating baking technology to ensure the adhesion of the coating and the uniformity and saturation of the color.

(2) The required colors can be provided according to customer requirements, and various special coatings can also be provided.

The aluminum honeycomb plate shall be installed in place according to the plate number on the plate distribution drawing, and the angle codes installed at the gelatin joint shall be assembled, and whether the angle codes of the two adjacent plates are staggered shall be checked. The test assembly shall be carried out to check the levelness and verticality, then the test shall be assembled with stainless steel bolts, and the test shall be fixed on the main and auxiliary keels. The horizontal and vertical seam clearance shall be adjusted to meet the requirements before fixing.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Aluminum honeycomb plate aluminum plate can be made of light quality, high strength, good rigidity, plate surface is very flat plate, can be used for structure, cushion, partition and decoration and other occasions, such as can be used for curtain wall, building partition, sound-absorbing board, high-speed train, ship, car, etc. In addition to the quality of the honeycomb aluminum plate is related to the selected material, it mainly depends on the bonding quality, and its key technical index is the peel strength. The factors affecting the peel strength of the honeycomb aluminum plate will be described below.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

The installation of the honeycomb aluminum plate column shall first connect the column with the connecting piece, and then connect the connecting piece with the embedded part of the main body, and adjust and fix it. The installation elevation deviation of two adjacent columns shall not be greater than 3mm, the maximum elevation deviation of columns on the same floor shall not be greater than 5mm, and the distance deviation of two adjacent columns shall not be greater than 2mm. The elevation deviation of column installation shall not be greater than 3mm, the front and rear deviation of axis shall not be greater than 2mm, and the left and right deviation shall not be greater than 3mm.

Recommended:What are the specifications of aluminum corrugated board