China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Installation of wood grain aluminum honeycomb panelIt should be placed in place according to the plate number on the plate distribution diagram, the angle codes installed at the gelatin seam parts should be assembled, and check whether the angle codes of the two adjacent plates are staggered, try to assemble and check their levelness and verticality, then assemble with stainless steel bolts, try to fix them on the main and auxiliary keels, adjust the horizontal and vertical seam clearance to meet the requirements, and then fix them.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The flanging installation method is to process the flanging for installation when processing the aluminum honeycomb panel. The installation only needs to comfort the connection with the keel and the glue seam. The suitable glue seam width is ≥ 10mm. This method is convenient to install, but the processing is slightly complicated and is not suitable for modeling curtain wall panels.

stainless steel honeycomb plateEasy and fast installation.

The installation of the wood grain aluminum honeycomb panel installation column shall first connect the column with the connecting piece, and then the connecting piece shall be connected with the embedded part of the main body, and shall be adjusted and fixed. The installation elevation deviation of two adjacent columns shall not be greater than 3mm, the maximum elevation deviation of columns on the same floor shall not be greater than 5mm, and the distance deviation of two adjacent columns shall not be greater than 2mm.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

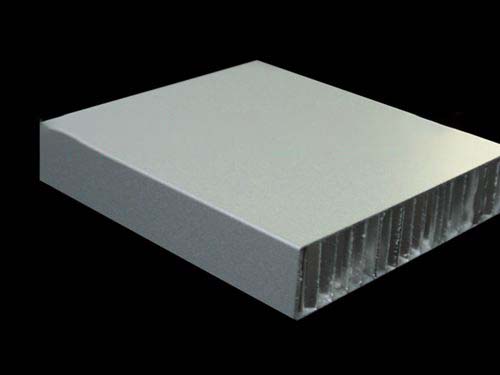

Honeycomb aluminum plate with high strength alloy aluminum plate as the surface, the bottom plate and aluminum honeycomb core by high temperature and high pressure composite manufacturing, is a kind of composite plate, it uses the honeycomb sandwich structure, excellent material selection, advanced technology and reasonable structure, wood grain aluminum honeycomb plate installation in color, flatness and other aspects have great advantages.

Installation of aluminum honeycomb panel erection

1. Connect the corner code with anti-corrosion glue, add square gasket, add spring washer, add opposite bolt and fix the keel by hand.

2. Fix the joint identification position at the upper opening of the keel, and temporarily fix the spot welding angle code.

3. The vertical error of aligning the keel with a 2-meter ruler is 2mm until it is adjusted in three dimensions.

4, review the diameter, according to the pay-off method for comparison.

5, full welding angle code and embedded parts contact position, require welding height 6-8mm, smooth lines, no bubbles and slag inclusion.

6, to remove slag rust, two-time anti-rust paint coating.

Recommended:Product Features of Punched Aluminum Honeycomb Panel

Product Features of Wood Honeycomb Aluminum Sheet