China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

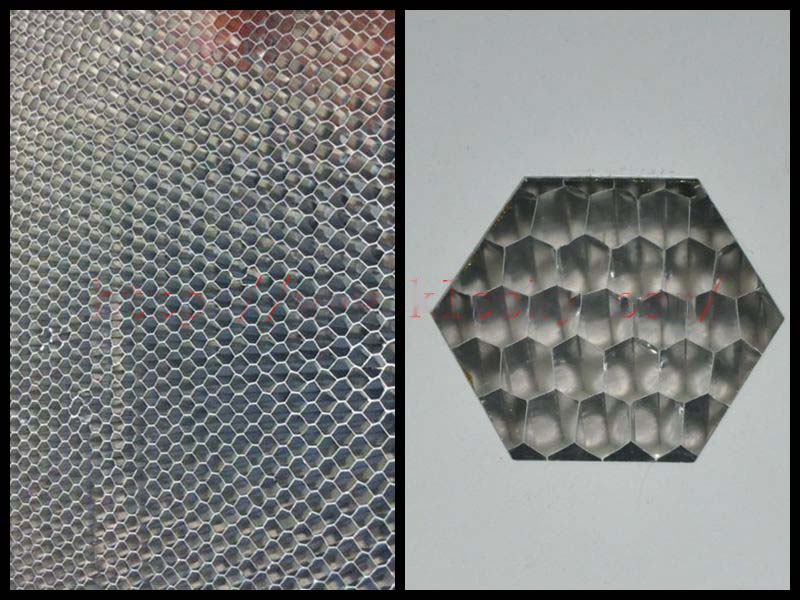

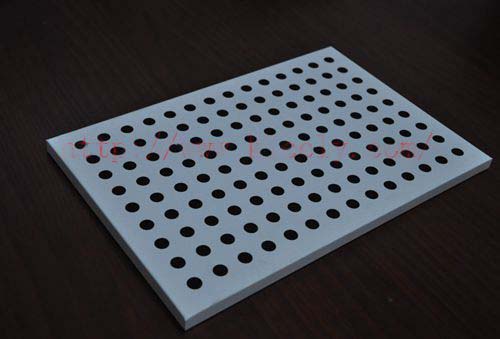

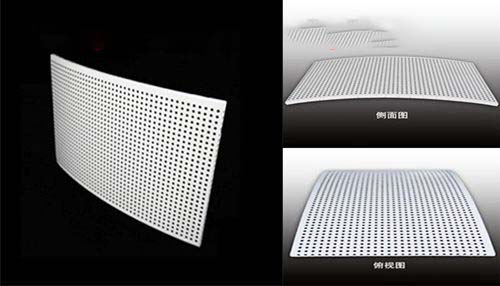

Punched aluminum honeycomb panelIt is a small hole that is punched out according to a certain rule on the surface of the aluminum honeycomb panel. It is not only beautiful and generous, but also the sound-absorbing paper hidden inside has a very good attraction effect. It is suitable for conference rooms, auditoriums and other occasions.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The weight of honeycomb panel with the same rigidity is only 1/5 of that of aluminum veneer and 1/10 of that of steel plate. The interconnected aluminum honeycomb cores are like countless I-beams. The core layers are distributed and fixed in the whole plate surface to make the plate more stable. Its wind pressure resistance is much higher than that of aluminum veneer and aluminum veneer. It is not easy to deform and has good flatness, even if the cell size of honeycomb panel is large.

Main features of punching aluminum honeycomb panel:

1, light, low installation load;

2, high flatness, not easy to deformation, high safety factor;

3. It has very good sound absorption performance.

4, more ornamental.

There are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely; the sliding installation buckle system will not cause structural deformation during thermal expansion and contraction, so it can ensure extremely high flatness.

stainless steel honeycomb plateEasy and fast installation.

Punched aluminum honeycomb panels are made of adhesive: two-component polyurethane high-temperature curing adhesive, which is compounded by full-automatic honeycomb panel composite production equipment under pressure and high temperature, overcoming the brittleness of the bonding layer of honeycomb panels in the past.

The roll forming technology is adopted to complete the forming of the front and back skins, the full-automatic machine equipment is folded, and the front and back skins are tightly engaged at the installation edge.

The inner layer is a special hexagonal aluminum honeycomb, composed of aluminum alloy with a hardness of H19, which acts as a core plate adhered in the sandwich structure and bears pressure in the tangential direction.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

These mutually restrained dense honeycombs are like many small I-beams, which can be dispersed to bear the pressure from the direction of the panel, so that the plate is evenly stressed and ensures that the panel can still maintain a high flatness in a large area. The installation is installed on both sides without mechanical damage.

Recommended:Product Features of Wood Honeycomb Aluminum Sheet