China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

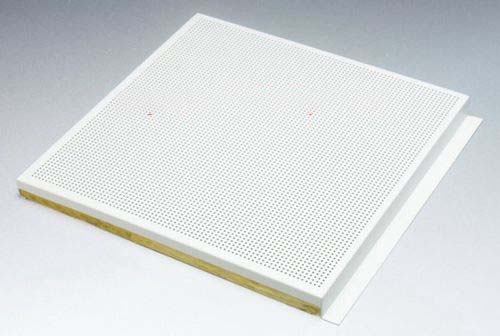

Wood honeycomb aluminum plateInterconnected honeycomb cores are like countless I-beams. The core layer is distributed and fixed in the whole plate surface, which is not easy to produce shear, making the plate more stable, more resistant to bending and compression. Its wind pressure resistance greatly exceeds that of aluminum-plastic plate and aluminum veneer, and has the characteristics of not easy to deform and good flatness.

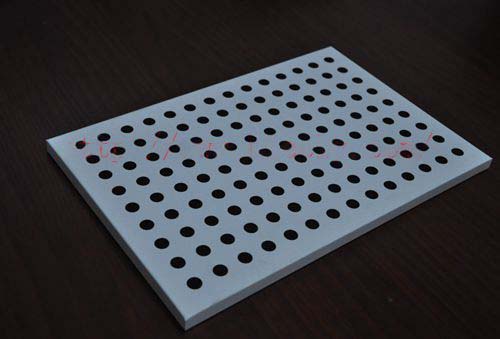

Honeycomb aluminum plateIt is a composite material with large surface formed by hot pressing of high-grade aluminum alloy panel, back plate and aluminum honeycomb core material. The product specifications are various, and the surface can be embossed, mirror, embossed, wire drawing, electroplating, anodizing, matte, bright light and metallic color, etc., which can meet the application requirements of various places.

Even if the size of the honeycomb panel is very large, it can achieve extremely high flatness. Because the honeycomb core in the honeycomb composite panel is divided into many closed cells, the air flow is prevented, and the heat and sound waves are greatly hindered. Therefore, it has the effect of heat insulation, heat preservation and sound insulation.

A general term for boards made of wood, wood scrap, wood fiber or other plant fibers as raw materials, plus adhesives and other additives. Wood-based panels have better dimensional stability than natural wood, and are widely used in construction, vehicles, ships, furniture, packaging, etc. The production of wood-based panels is the main way of comprehensive utilization of wood.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Wooden honeycomb aluminum plate is a series of metal composite panels developed in combination with the aviation industry composite honeycomb panel technology. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Honeycomb aluminum plate shall be installed in place according to the plate number on the plate allocation drawing. The installation angle code at the gelatin seam part shall be assembled. The wooden honeycomb aluminum plate shall be checked to see if the angle code of the adjacent two plates is staggered. The test assembly shall be carried out to check its levelness and verticality. Then the test shall be assembled with stainless steel bolts. The test shall be fixed on the main and auxiliary keels. The horizontal and vertical seam clearance shall be adjusted to meet the requirements.

Recommended:What is the performance of composite honeycomb aluminum plate