China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Latch composite floorThe buckle type is closely combined, completely overcoming the problems of seam separation, warping and bulging caused by the change of the floor by the external cold, heat, dry and wet. In the paving process, it is completely nail-free, glue-free and keel-free, and is directly laid on the ground, thus saving the height of the room, and can be repeatedly disassembled and used, which is economical and practical.

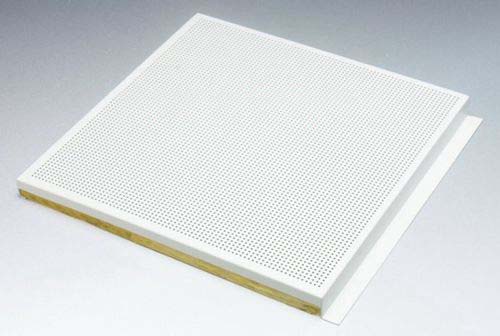

aluminum honeycomb panelIs based on aluminum metal plate, with ordinary aluminum veneer antibacterial, anti-corrosion, long service life characteristics, because of its special design it sound insulation, seismic, moisture-proof effect is also very prominent.

The lock floor has stricter requirements on the substrate. Under normal circumstances, the lock floor can withstand a lot of tension, so the density, relative humidity, expansion and other physical properties of the lock floor substrate are more stable.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Latch composite floor paving is simpler, the joints are tighter, the overall paving effect is good, the tongue and tongue of the floor are finer and tongues, and smoother, thus reducing the error of manual paving. Due to the locking force of the lock floor, the floor extends to the whole circumference with the change of temperature, avoiding local uplift, solving the internal deformation problem of the floor, and the overall paving effect is good.

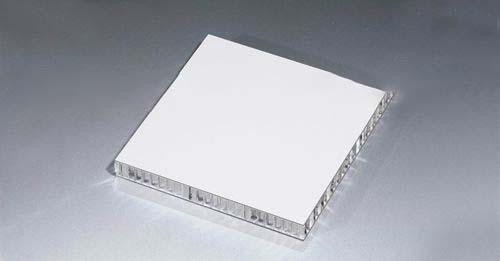

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Solid wood composite and solid wood do not recommend locking, or flat buckle is better. Because the deformation rate of solid wood composite and solid wood is relatively high, it is easy to expand or contract, and if the force is greater, it may directly break the lock. When installing the flat buckle floor, reserve sufficient shrinkage joints on the wall and install springs in the shrinkage joints.

Latch composite floor paving is simpler, the seams are tighter, and the overall paving effect is good-the lock floor adopts an advanced laser calibration quality detection system in the production process, I .e. laser automatic correction, which avoids wave height difference and makes the tongue and tongue finer and tongue flatter. Latch floor with industrial standard instead of manual paving standard, reducing the error of manual paving, paving the floor and the floor gently tap into the slot.

Since there is no need to use glue, it can be directly assembled. The environmental problems caused by the glue residue have become a thing of the past. After paving, the floor becomes very clean and tidy without peculiar smell. According to the needs of users, this floor can be used for 5 times.

推荐:How about the performance of corrugated composite aluminum plate