China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum corrugated board manufacturersIn cold areas, the upper and lower ends of the corrugated channel are sealed. During the day, under the sunlight, the heat energy is stored to reduce the loss of indoor heating heat, and it has heat preservation performance. The waste material in the project can be recycled by 100, which is environmentally friendly and pollution-free.

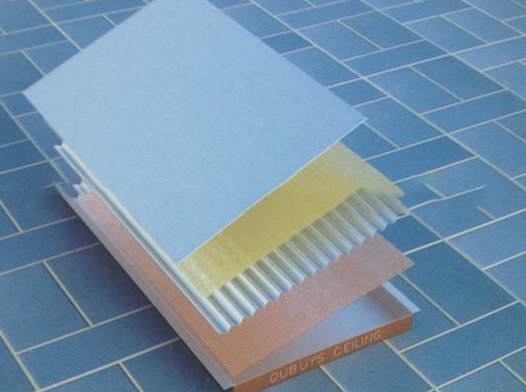

The core board of aluminum corrugated board is water corrugated type, which forms an air channel between the panel and the back plate. It is a hollow board system and is an excellent product of heat insulation. Under the action of solar radiation, the air in the channel heats up and flows upward to take away heat, which has heat insulation performance.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Aluminum corrugated board manufacturers are light in weight and economical: when aluminum corrugated board is 6mm thick, the specific gravity is 4.3kg/㎡. due to the small heavy load of surface materials, the structural supporting keel can be reduced, which is more economical.

Product use:

Building exterior wall, beam column, balcony, waiting room. Waiting room, conference hall, opera house, stadium, reception hall and so on.

Now there have been many plastic extrusion corrugated board, corrugated aluminum, corrugated aluminum, there are transparent, there are opaque and colored, as well as multi-layer composite hollow. Because of its good plasticity, it can better adapt to the requirements of various architectural shapes, but compared with the service life, aesthetic degree and durability and other performance color steel corrugated board is better.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The Products of aluminum corrugated board manufacturers are widely used in electrical appliances, heat preservation, machinery manufacturing, automobiles, electronics, aerospace, industry, molds, construction, printing and other industries. High purity Products: pure aluminum plate (flat plate. diamond plate. ginned plate). Aluminum coil. Alloy aluminum plate, modern, mechanized production equipment can provide ultra-wide ultra-thick ultra-hard aluminum plate.

stainless steel honeycomb plateEasy and fast installation.

Although the strength of pure aluminum can be strengthened is not high, it can be more than doubled by cold working, and it can be alloyed by adding magnesium, zinc, copper, manganese, silicon, lithium, scandium and other elements, and then further strengthened by heat treatment. Its strength is comparable to high-quality alloy steel.

Recommended:What are the characteristics of the arc aluminum honeycomb panel process