China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum Honeycomb Panel SpecificationStrictly control the casting production process. The control range of the chemical composition of the ingot must be as small as possible, and the chemical composition must be uniform. In addition, the melting process, the casting process, and the homogenizing treatment process must be strictly performed.

Strictly control the anodizing temperature. From the anodic oxidation film formation mechanism, anodic oxidation temperature is low, the formation of the oxide film is dense, the porosity is small, aluminum honeycomb panel specifications with the increase of anodic oxidation temperature, the oxide film gradually become loose, the porosity gradually becomes larger, the color of the film layer gradually becomes darker with the increase of temperature. Therefore, the anodic oxidation temperature is an important factor in determining the density of the oxide film, and it is also an important factor in determining the color uniformity of the oxide film.

For the anodizing treatment of aluminum plates, aluminum-plastic plates and honeycomb panels, attention should be paid to the uniformity of the thickness of the anodized film, the uniformity and reproducibility of the color.

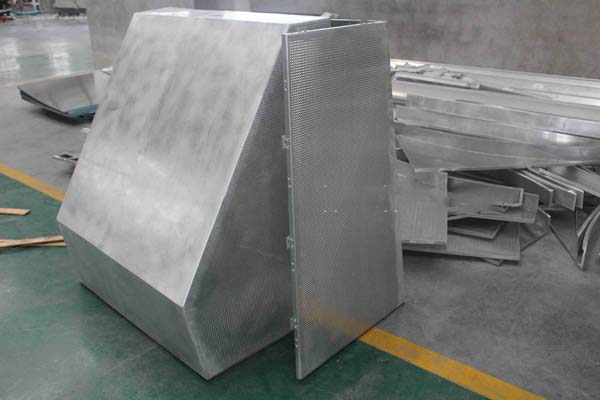

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

To ensure the uniformity of anodic oxide film thickness, color uniformity and reproducibility, it is necessary to strictly control the chemical composition of aluminum alloy and the production process of anodic oxidation.

Strictly control the anodic oxidation current density. With the increase of the current density, the color of the oxide film gradually becomes darker, the thickness of the film becomes thicker and then thinner, the reason is that the current density increases,aluminum honeycomb panelThe pore size of the membrane increases and is easy to color; the current density decreases, the growth rate of the membrane decreases, and the membrane layer is dense, so as the current density increases, the color of the oxide film gradually becomes darker.

The aluminum foil adopts roll forming technology to complete the forming of the front and back skins. There are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely. The slidable installation buckle system will not cause structural deformation during thermal expansion and contraction, so it can ensure extremely high flatness. The inner layer is a special hexagonal honeycomb, which is called \'aluminum honeycomb panel\' because of its honeycomb shape \'.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Sound insulation, heat insulation and shockproof: because the aluminum honeycomb core in the aluminum honeycomb curtain wall panel is divided into many closed cells, the flow of air is prevented, heat and sound waves are not easy to spread, the sound source of 100-3200HZ noise can reach 20-30DB, and the thermal conductivity is only 0.0424/m.k.

Recommended:Development trend of stone aluminum honeycomb panel manufacturers