China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

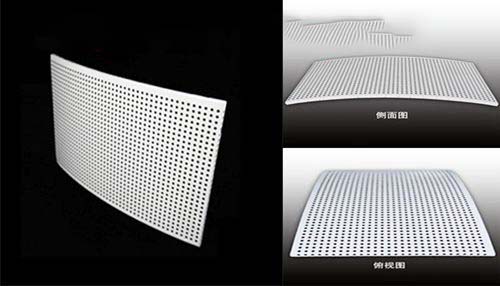

Arc Aluminum Honeycomb Panel ProcessIs a combination of aviation industry composite honeycomb panel technology and the development of metal composite panel Products. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

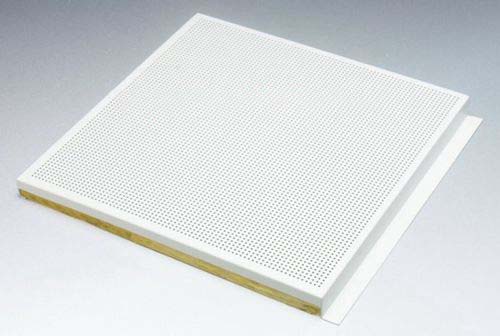

Honeycomb aluminum plate with high strength alloy aluminum plate as the surface, the bottom plate and aluminum honeycomb core by high temperature and high pressure composite manufacturing, is a kind of composite plate, it uses honeycomb sandwich structure, excellent material selection, advanced technology and reasonable structure, in color, flatness and other aspects have great advantages.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Arc Aluminum Honeycomb Panel Process Coating Technology

(1) The original coating baking technology is adopted to ensure the adhesion of the coating and the uniformity and saturation of the color.

(2) The required colors can be provided according to requirements, and various special coatings can also be provided.

Arc aluminum honeycomb panel process generally uses fluorocarbon roll coated aluminum panel. The most important point of fluorocarbon roll-coated aluminum plate is the use of a continuous roller coating process, the aluminum plate is painted at one time to ensure that the product has no color difference, good coating flatness and reliable quality.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

At the same time, it can keep the color of the outer wall of the building bright for a long time. After long-term sun and rain or industrial waste gas pollution, it is obvious that the roll-coated board is cleaner and brighter than the spray-coated board, and has good adhesion and weather resistance. The arc aluminum honeycomb board process is recognized as the first-class material by the world\'s architects. Jinbatai arc aluminum honeycomb board.

forming technology

(1) Through a series of molds, the stress inside the plate is fully released.

(2) to protect the surface of the panel coating is not damaged, more durable. The entire production process ensures the high precision of the plate processing size.

(3) The continuous thermal composite production process is efficient and fast.

stainless steel honeycomb plateEasy and fast installation.

Recommended:Working principle of aluminum honeycomb plate punching