China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel useFor the modern furniture industry with strict environmental protection requirements, using aluminum honeycomb panels as furniture processing materials is a good material choice in the new century. Its completely non-toxic green quality allows furniture manufacturers to reduce unnecessary environmental protection procedures when processing furniture. In addition, aluminum honeycomb panels can be diversified such as solid wood, aluminum plate, gypsum board and natural marble stone, which can be made into honeycomb panels with convenient material selection.

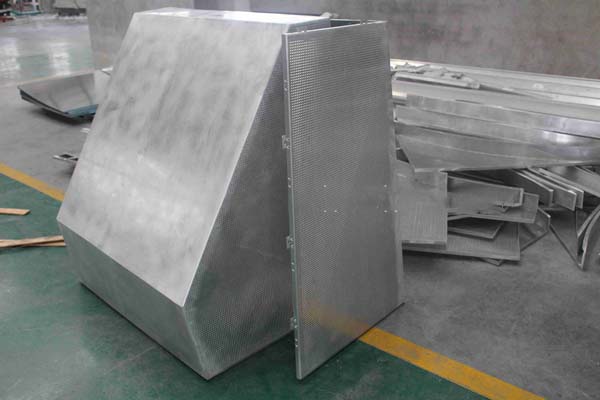

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Aluminum honeycomb panel partition: the emergence of aluminum honeycomb panel partition, breaking the traditional partition mode, with its noble, fresh and stylish style, won the market share of medium and high-end office space.

The aluminum honeycomb panel mainly uses high-quality 3003H24 alloy aluminum plate or 5052AH14 high manganese alloy aluminum plate as the base material. The thickness of the panel is 0.8~1.5mm fluorocarbon roll-coated board or light-resistant baking varnish. The light-resistant baking varnish is stronger than PVDF in scratch resistance, acid rain corrosion discoloration and self-cleaning. The thickness of the bottom plate is 0.6~1.0mm, and the total thickness is 25mm.

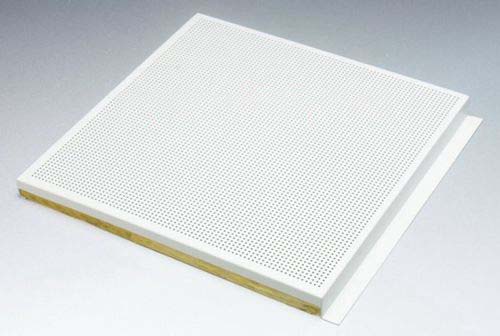

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The aluminum honeycomb core is made of multiple layers of aluminum foil bonded together and then expanded into a regular honeycomb shape. And suitable for high quality honeycomb core face material paste and other purposes.

Aluminum honeycomb panel is easy to dismantle and assemble, and will not break down the plate. Due to its light weight and convenient transportation, it can be transported to different places for repeated use. This is the other partition plate can not be compared.

Uses: farmers, heating equipment, auto parts, stoves, microwave ovens, electric pots, drying ovens, ovens, heaters, car silencers, fuel tanks, car exhaust pipe accessories, exterior wall decoration materials, air ducts.

stainless steel honeycomb plateEasy and fast installation.

The use of aluminum honeycomb panels is used in building ceilings. The application of honeycomb aluminum ceiling systems has been for a long time. From the panel material, shape, installation system, color and surface treatment of aluminum honeycomb panels, engineers are provided with a wide range of choices, which can be seen from a variety of angles. Show the beauty of aluminum honeycomb panels, with excellent design freedom.

Recommended:How about the performance of corrugated aluminum plate