China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

single-sided corrugated aluminum sheetIn the production and operation, sometimes there will be a variety of bad situations, such as: cardboard wrinkle, corrugated paper wrinkle, broken stare blankly, edge peeling, collapse stare blankly, stare blankly crack, stare blankly deformation, rubbing plate, cardboard surface showing stripe marks, etc. All kinds of faults such as these are generally related to insufficient heat, insufficient braking force, wear of roller neck bearings, abnormal gluing, etc. It is necessary to distinguish the reasons and take corresponding measures to deal with them.

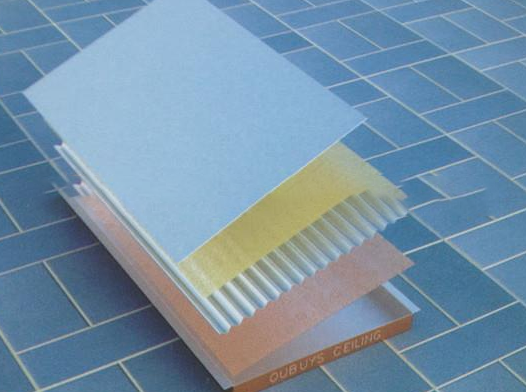

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The method for checking and adjusting the gap between the rubber coating roller and the lower corrugated roller for single-sided corrugated aluminum plate is to clamp the gap between the roller and the roller with a 0.1-0.2mm thick paper strip (one or two sheets), and then adjust the pressure between the roller and the roller to make the hand feel have certain resistance when pulling out the clamped paper strip, and the axial direction should be consistent everywhere.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

When running and using, one is to adjust the gap between the rubber roller and the rubber roller through the action of the worm gear, worm and gear, and the other is to adjust the gap between the rubber roller and the lower corrugated roller through the action of the worm gear, worm and hand wheel.

If the rubber coating roller and the lower corrugated roller are not parallel, the single-sided corrugated aluminum plate will obviously have a loose end and a tight end. This requires adjusting the screws on both sides of the limiting piece to drive the connecting rod to move so that the uniform rubber roller is adjusted to be parallel to the lower corrugated roller. The same is true for the gap adjustment method between the rubber roller and the rubber roller.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

In general, the gap between the glue roller and the lower corrugated roller should be 0.1-0.3mm, and the normal gap between the glue roller and the glue roller should be 0.2-0.3mm. The glue roller and the lower corrugated roller should also be kept parallel, because if they are not parallel, the glue will be unevenly applied and the bonding between the face paper and the core paper will be poor.

Recommended:Installation of Perforated Aluminum Honeycomb Panels