China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

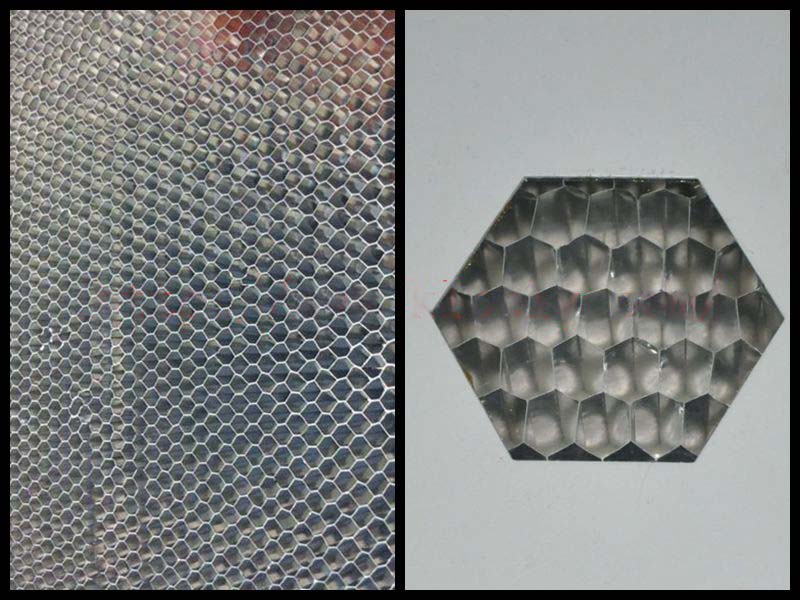

Dimension of Arc Aluminum Honeycomb PanelIt is a series of metal composite panel Products developed in combination with composite honeycomb panel technology. The product uses a honeycomb sandwich structure, that is, a high-strength alloy aluminum plate with a decorative coating with excellent weather resistance is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

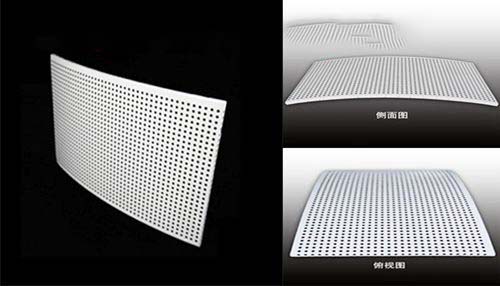

Aluminum honeycomb panel product series has the advantages of excellent material selection, advanced technology and reasonable structure. It not only has excellent performance in large scale and flatness, but also has many choices in shape, surface treatment, color, installation system and so on. In addition to the use of aluminum alloy panels, but also according to customer needs to choose other materials.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The surface adopts advanced pre-roller coating fluorocarbon paint process, which can be maintained for thirty years without discoloration. The company adopts two-component polymer epoxy film and two-component modified epoxy resin, through the fully enclosed dust-free operation,aluminum honeycomb panelThe size is made by German full-automatic honeycomb panel composite production equipment through pressure and high temperature, so that the aluminum curtain wall honeycomb panel is more firmly bonded, more resistant to bending, the plate is more straight, and the quality is more reliable.

Honeycomb core specifications can be expressed in two ways: honeycomb cell inscribed circle diameter (English units) and aluminum foil thickness/cell edge (metric units). China\'s national standard is expressed in aluminum foil thickness/cell edge length.

The weight of the honeycomb sandwich panel with the same stiffness of the arc-shaped aluminum honeycomb panel is only 1/5 of the aluminum plate and 1/10 of the steel plate. The total thickness is 15mm, the panel is 1.0mm, and the bottom plate is 0.8mm aluminum honeycomb panel, which weighs only 6kg/m2.

stainless steel honeycomb plateEasy and fast installation.

Interconnected honeycomb cores are like countless I-beams. The core layer is distributed and fixed in the entire board surface. The size of the arc-shaped aluminum honeycomb panel is not easy to produce shear, which makes the panel more stable, more resistant to bending and compression. Its wind pressure resistance greatly exceeds that of aluminum-plastic panel and aluminum veneer, and has the characteristics of not easy deformation and good flatness.

Even if the size of the honeycomb panel is large, Jinba Tai can achieve extremely high straightness. Because the honeycomb core in the honeycomb composite panel is divided into many closed cells, the air flow is prevented, and the heat and sound waves are greatly hindered. Therefore, it has the effects of heat insulation, heat preservation and sound insulation.

Recommended:Installation method of honeycomb aluminum composite board