China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

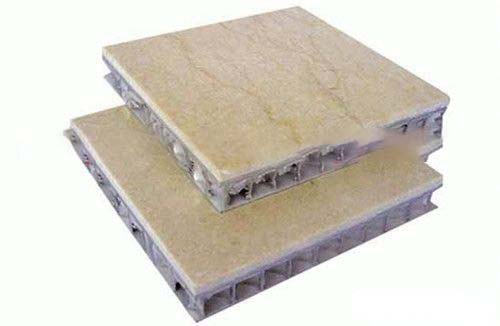

Honeycomb aluminum composite plateThe corrugated paper layer and the flat paper layer are arranged between the two layers in parallel and are pasted and formed, and the corrugated surface of the corrugated paper layer is generally perpendicular to the surface layer. Corrugated paper composite board is composed of two or more layers of corrugated cardboard superimposed adhesive pressure, the arrangement direction of the corrugated paper layer in the adjacent layer is the wrong angle.

Construction preparation of honeycomb aluminum plate composite plate: build temporary facilities on site such as office buildings, material processing workshops, etc., install construction scaffolding and vertical transportation equipment, set up construction electricity and set up construction work surface signs (such as floor signs, etc.); Install and design composite aluminum plate processing equipment.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The framework shall be installed correctly according to the setting-out positioning, and its horizontal and vertical spacing and flatness must meet the design requirements. In order to prevent the curtain wall from deformation due to construction and weather, the living hinge parts of the skeleton must be constructed in strict accordance with the design requirements.

Honeycomb aluminum plateAfter the installation of the composite board frame is completed, it shall comprehensively check the levelness, verticality, flatness, spacing size, etc. of the frame, and check whether the embedded parts and hinge points are firm and reliable. The construction of the next process can only be carried out after passing the test.

In order to ensure the correctness of the installation and improve the work efficiency, after the installation of the skeleton is completed, the number shall be written at the corresponding position according to the figure, corresponding to the number of the prefabricated aluminum plate; The fixing connection shall be firm and reliable, and the size of the gap between the aluminum plates shall not exceed the design requirements, because this is the condition to ensure that the adhesive will not be damaged under the conditions of cold shrinkage and thermal expansion, which are calculated in the design.

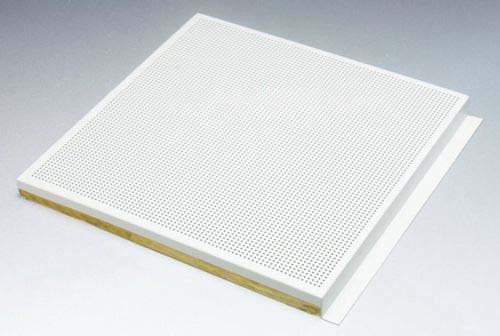

stainless steel honeycomb plateEasy and fast installation.

The installation of the honeycomb aluminum plate column shall first connect the column with the connecting piece, and then connect the connecting piece with the embedded part of the main body, and adjust and fix it.

The installation of the honeycomb aluminum plate column shall first connect the column with the connecting piece, and then connect the connecting piece with the embedded part of the main body, and adjust and fix it. The installation elevation deviation of two adjacent columns shall not be greater than 3mm, the maximum elevation deviation of columns on the same floor shall not be greater than 5mm, and the distance deviation of two adjacent columns shall not be greater than 2mm.

Recommended:Installation effect of composite wall gusset plate