China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Honeycomb aluminum ceilingMeasuring and setting out Measuring and setting out is the most precise process in the ceiling project, which plays an important role in controlling the flatness of the ceiling. The measurement and setting out shall comply with the overall measurement and control procedure before the local measurement and control procedure, and the horizontal control line of the ceiling keel shall be released by theodolite according to the original structural axis.

According to the data required by the standard, the arch control line of the suspended ceiling keel is provided on the basis of the elliptical curve arch of the suspended ceiling. The measurement and setting-out requires scientific method, orderly calculation, step-by-step verification and reliable results.

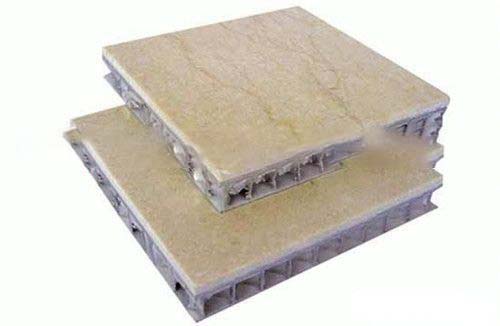

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Honeycomb aluminum plate is a series of metal composite panel Products developed in combination with the aviation industry composite honeycomb panel technology. The product uses a honeycomb sandwich structure, that is, a high-strength alloy aluminum plate with a decorative coating with excellent weather resistance is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Honeycomb aluminum plateCeiling installation points:

(1) In order to avoid large deformation of the ceiling panel during installation, there are 4 to 6 lifting points at the edge of the ceiling panel. (The wind force when installing the ceiling plate should not be greater than level 2) When the ceiling plate is just lifted, the plate surface is perpendicular to the ground. When the upper end reaches the installation height, pull up the other side, and the lifting edge should be the long side.

(2) After hanging the ceiling plate to the required height, hook the ceiling keel with the hanging plate pendant, and do not lock the screws for the time being. When a row of ceiling panels is installed, the ceiling panels are adjusted to the same height by the height adjustment screws. Lock the side screws after height adjustment.

(3) After the adjustment of all ceiling plates is completed, add a sealing strip, and fill the groove of the profile with sealant before pressurizing the sealing strip.

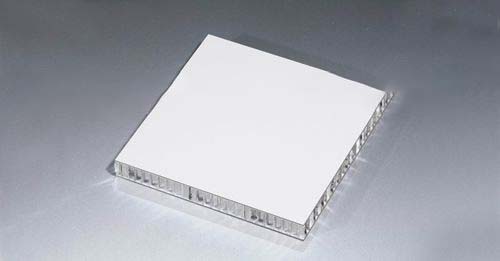

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

In addition, the panel in addition to the use of aluminum alloy, but also according to customer needs to choose other materials, such as: copper, zinc, stainless steel, pure titanium, fire board, Zhong Qian board, marble, aluminum-plastic board and so on.

Honeycomb aluminum plate manufacturing technology from the aviation industry, to pre-roll coated aluminum alloy panel and back plate, the middle of the aluminum alloy honeycomb core, the use of high-quality two-component PU glue hot-pressed composite. As a ceiling system, the honeycomb aluminum ceiling is not only durable, the panel is oversized, but also has excellent flatness. Aluminum honeycomb panel can be bent, good processing performance, surface treatment has a variety of options.

Recommended:The development trend of modeling aluminum honeycomb panel manufacturers