China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

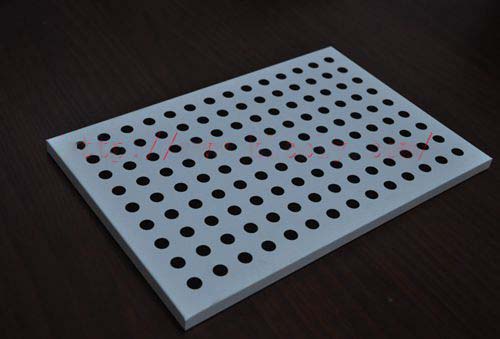

single-sided corrugated aluminum sheetIt is a new type of composite aluminum plate curtain wall material made of 0.6-0.8mm panel, 0.4mm bottom plate, and 0.2mm corrugated aluminum plate in the middle. The surface of the corrugated core material is coated with thermosetting epoxy resin adhesive, and the aluminum plate product is compounded by heating and pressing. Its compounding method is similar to the form of corrugated carton board.

Corrugated aluminum plate is also known as pressure aluminum plate, wave aluminum plate or aluminum tile. It is one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Single-sided corrugated aluminum plate has the characteristics of light weight, high strength, rich color, convenient construction, earthquake resistance, fire prevention, rain prevention, long life, maintenance free, etc., and has been widely used. Now there have been many plastic extrusion corrugated board, corrugated aluminum, corrugated aluminum, there are transparent, there are opaque and colored, as well as multi-layer composite hollow.

Because of its good plasticity, it can better adapt to the requirements of various architectural shapes, but compared with the service life, aesthetic degree and durability and other performance color steel corrugated board is better.

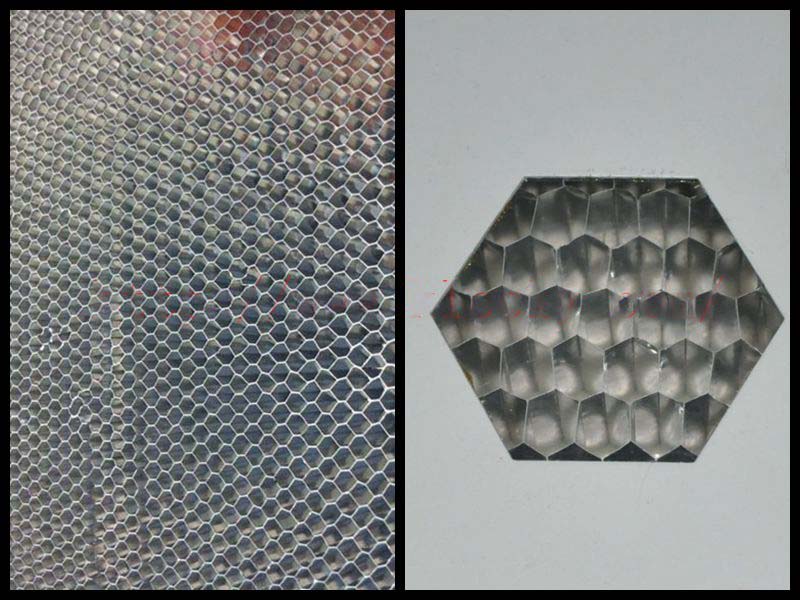

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The single-sided corrugated aluminum sheet production line is composed of three parts: a web support, a single-sided corrugated forming machine, and a rotary slitting machine. The web is used as the paper material to continuously operate and automatically cut into high-quality single-sided corrugated cardboard of the required specifications. The production line has advanced process, high degree of automation, low power consumption and high efficiency, and is suitable for mass production in small and medium-sized carton factories.

stainless steel honeycomb plateEasy and fast installation.

The single-sided corrugated aluminum plate adjusts the tension through the paper guide roller, the upper preheating roller controls the humidity, slides through the top of the upper corrugated roller into the corrugated channel between the heated upper and lower corrugated rollers, presses and irons at the meshing point on the central connection line of the two rollers, and runs tightly on the lower corrugated roller to the central connection line between the rubber coating roller and the lower corrugated roller, the glue is evenly coated on the top of the corrugated paper by the glue roller that forms a uniform layer of glue film on the surface after being scraped off by the glue roller.

Recommended:Working principle of corrugated alloy aluminum plate