China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

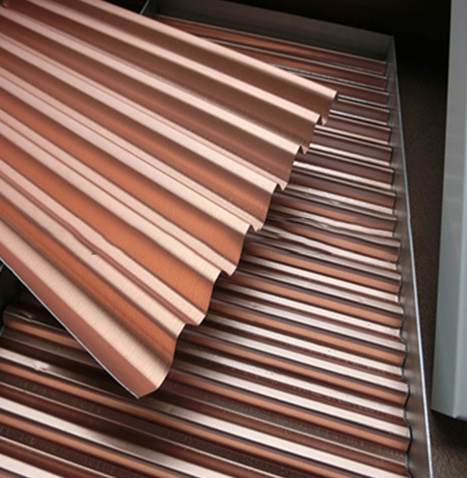

Corrugated alloy aluminum plateSuitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure housing roof, wall and interior and exterior wall decoration.

Corrugated alloy aluminum plate has the characteristics of light weight, high strength, rich color, convenient construction, seismic, fireproof, rainproof, long life, maintenance-free, etc., and has been widely used. Now there have been many plastic extrusion corrugated board, corrugated aluminum, corrugated aluminum, there are transparent, there are opaque and colored, as well as multi-layer composite hollow.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Corrugated alloy aluminum plate is added in the aluminum plate processing process of various alloy elements (the main alloy elements are copper, silicon, magnesium, zinc, manganese, secondary alloy elements are nickel, iron, titanium, chromium, lithium, etc.), in order to improve the mechanical properties of aluminum plate and chemical indicators. Alloy aluminum plate has some special properties that pure aluminum plate does not have, and is widely used in special environments, such as ships, refrigerators, molds, aerospace equipment, etc.

Corrugated aluminum plate is also known as pressure aluminum plate, wave aluminum plate or aluminum tile. It is one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The main element of corrugated alloy aluminum plate is aluminum, and a small amount of magnesium or other metal materials are added to strengthen its hardness. The aluminum alloy with Mg as the main added element is also called anti-rust aluminum alloy because of its good corrosion resistance. Because it is a metal, its thermal conductivity and strength are particularly prominent.

The linear expansion coefficient of corrugated alloy aluminum plate is about twice that of carbon steel and low alloy steel. The volume shrinkage rate of aluminum solidification is large, and the deformation and stress of the weldment are large. Therefore, measures to prevent welding deformation should be taken.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

It is easy to produce shrinkage cavity, shrinkage porosity, hot crack and high internal stress when the aluminum welding molten pool solidifies. Production can be used to adjust the composition of the welding wire and welding process measures to prevent hot cracks. When corrosion resistance permits, aluminum alloys other than aluminum-magnesium alloys can be welded with aluminum-silicon alloy welding wires.

Recommended:What are the advantages of punching aluminum corrugated board