China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

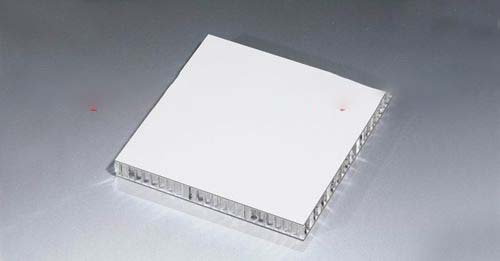

Marble aluminum honeycomb panelThe surface of the aluminum honeycomb panel is pasted with only 3-5mm natural stone. The standard panel weighs only 16kg per square meter, which is only 1/5 of the weight of the same thickness stone. It is convenient to install and has low cost. Good sound insulation and heat insulation effect; The impact strength is 10 times larger than that of granite with the same thickness.

Marble aluminum honeycomb panel not only maintains the decorative effect of the original natural stone, but also overcomes the shortcomings of natural stone, such as brittleness, fragility and heavy weight, and has better impact resistance and flexural strength, providing a new type of building stone Products for the majority of users.

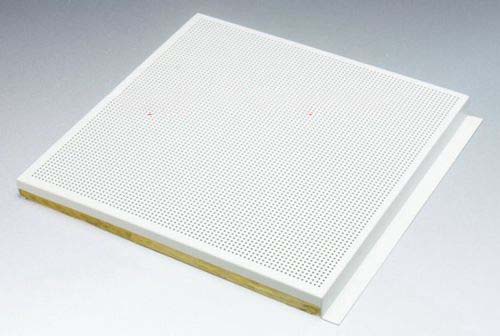

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

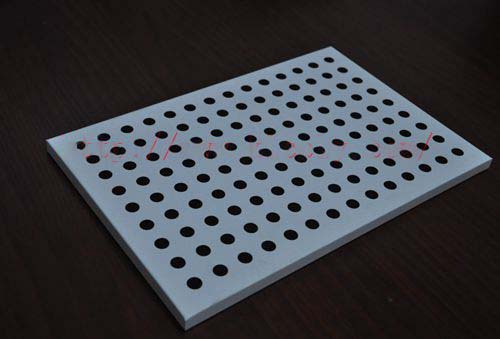

Rolling forming technology: in the process of making the panel and the back plate, the edge of the plate needs to be folded up. The folding machine used in the traditional process will form stress in the metal because of one-time rapid folding. Marble aluminum honeycomb panel will form micro damage to the metal and affect the service life of the metal.

The rolling forming technology uses ten rollers to gradually fold the edge of the plate to a preset angle, gradually forming to ensure the release of internal stress, and the damage to the metal itself is reduced to a minimum.

Aluminum honeycomb panel: aviation technology used in civil construction, vehicle and ship decoration. It is the application of aviation and aerospace materials in the field of civil construction.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The whole processing process is completed in a modern factory. Hot pressing molding technology is adopted. Due to the high thermal conductivity value between the aluminum skin and the honeycomb, the thermal expansion and cold contraction of the inner and outer aluminum skin are synchronized. There are small holes in the honeycomb aluminum skin, so that the gas in the plate can flow freely.

The sliding installation buckle system of marble aluminum honeycomb panel will not cause structural deformation during thermal expansion and contraction, so it can ensure extremely high flatness. Adopt adhesive: two-component polyurethane high-temperature curing adhesive, with full-automatic honeycomb board composite production equipment through pressurized high-temperature composite, to overcome the brittleness of the previous honeycomb board adhesive layer.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Aluminum honeycomb panel use

Building curtain wall decoration, ceiling, buses, trains, subway and rail transit vehicles, commercial transport vehicles and container car bodies, shipboard buildings, billboards, interior decoration projects.

recommended;The scope of application of imported honeycomb aluminum plate