China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

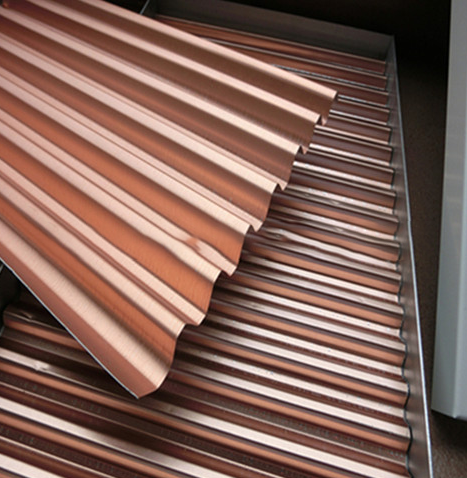

Aluminum corrugated board is used in industrial and civil buildings, warehouses, special buildings, roofs, walls and interior and exterior wall decoration of large-span steel structure houses. Corrugated aluminum plate (corrugated aluminum plate) has the characteristics of light weight, high strength, rich color, convenient construction, earthquake resistance, fire prevention, rain prevention, long life, maintenance free, etc., and has been widely used.

Read more

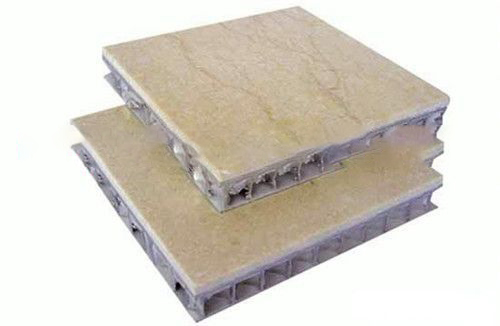

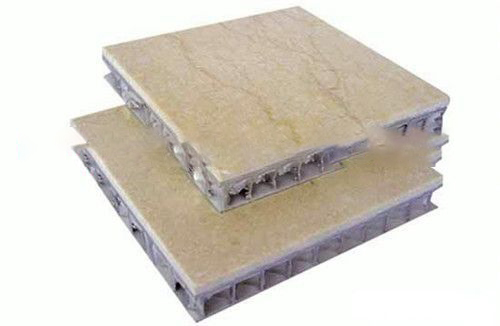

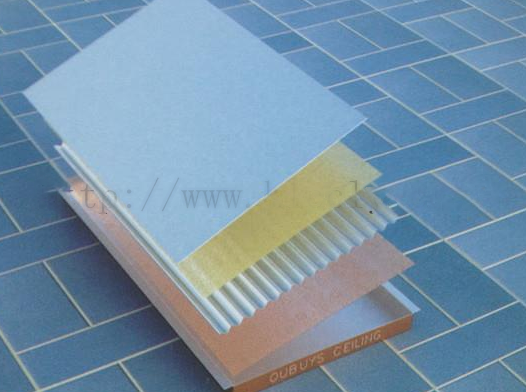

The size and shape of the incision shall be determined according to the assembly requirements. The inner surface of the outer aluminum plate of the honeycomb aluminum plate shall not be scratched when the aluminum core is cut off. The aluminum core of 0.3~0.5mm shall be reserved on the outer aluminum plate of each part;

Read more

Wood grain aluminum honeycomb panel: aviation technology is applied to civil construction, vehicle and ship decoration. It is the application of aviation and aerospace materials in the field of civil construction.

Read more

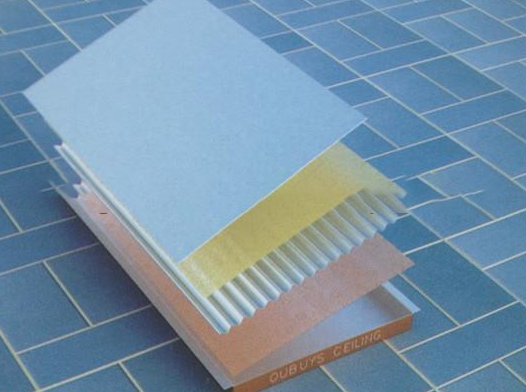

The aluminum corrugated composite board is made of AL3003H16-H18 material, the thickness of the panel is 0.8~1.0mm, the thickness of the back plate is 0.4~0.5mm (the same as the aluminum honeycomb board), the core board is made of AL100H16-H18, the thickness of the material is 0.2mm (the honeycomb core board is 0.06~0.07mm)

Read more

Aluminum corrugated composite board is a new type of composite aluminum curtain wall material made of corrugated aluminum board with 0.6-0.8mm bottom plate, 0.4mm middle 0.2mm corrugated aluminum board, coated with thermosetting epoxy resin adhesive on the surface of corrugated core material, and compounded by heating and pressing. Its compounding method is similar to that of corrugated cardboard box board.

Read more

The installation of punching honeycomb aluminum plate shall be placed in place according to the plate number on the plate distribution drawing, the installation angle code at the gelatin seam part shall be assembled, and whether the angle codes of two adjacent plates are staggered shall be checked for leveling and verticality, then assembled with stainless steel bolts, fixed on the main and auxiliary keels, and fixed after adjusting the horizontal and vertical seam clearance to meet the requirements.

Read more