China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

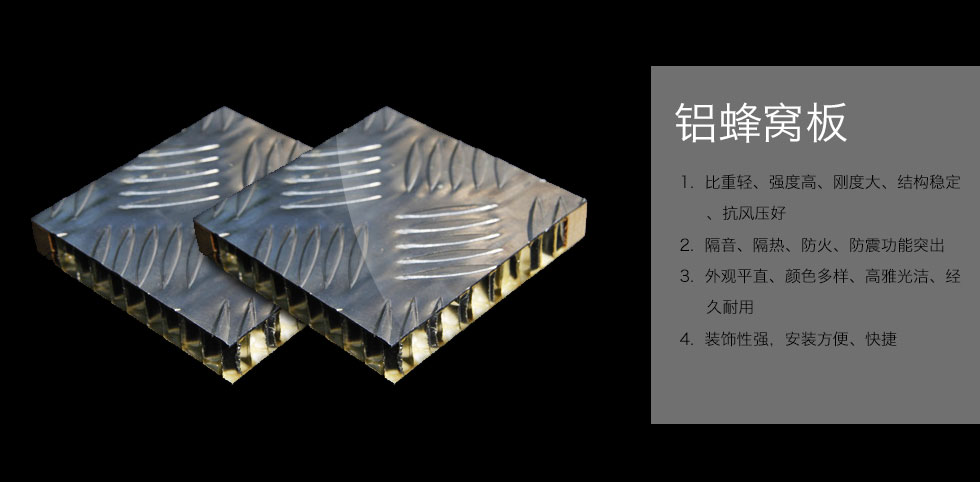

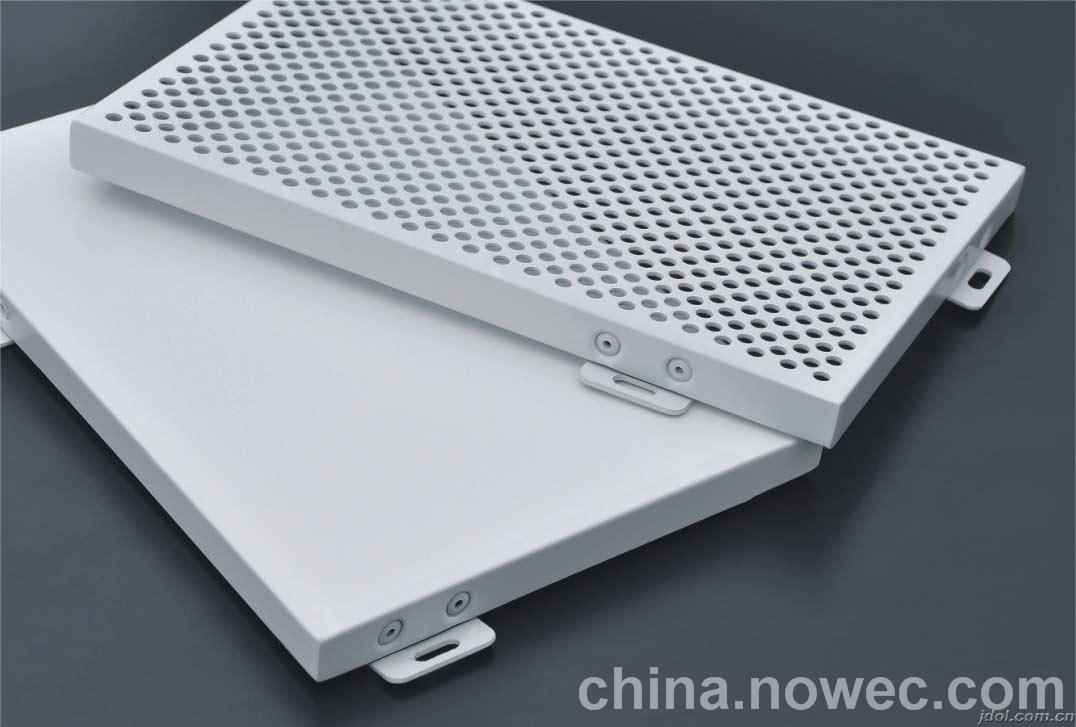

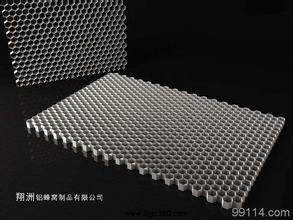

Aluminum honeycomb panel is a composite material bonded by aluminum honeycomb sheet and surface material. In summary, aluminum honeycomb panel has the following basic characteristics:

Read more

In the process of processing and compounding of aluminum honeycomb panels, according to the existing text data and drawings for sheet metal processing and aluminum honeycomb panel processing compound refinement design, there are the following steps

Read more

The aluminum honeycomb panel adopts composite honeycomb structure, and high-quality 3003H24 alloy aluminum plate or 5052AH14 high-manganese alloy aluminum plate is selected as the base material, and the aluminum alloy honeycomb core material is formed by hot pressing. Aluminum honeycomb panels provide architects with a wealth of choices from panel materials, shapes, seams, installation systems to colors and surface treatments

Read more

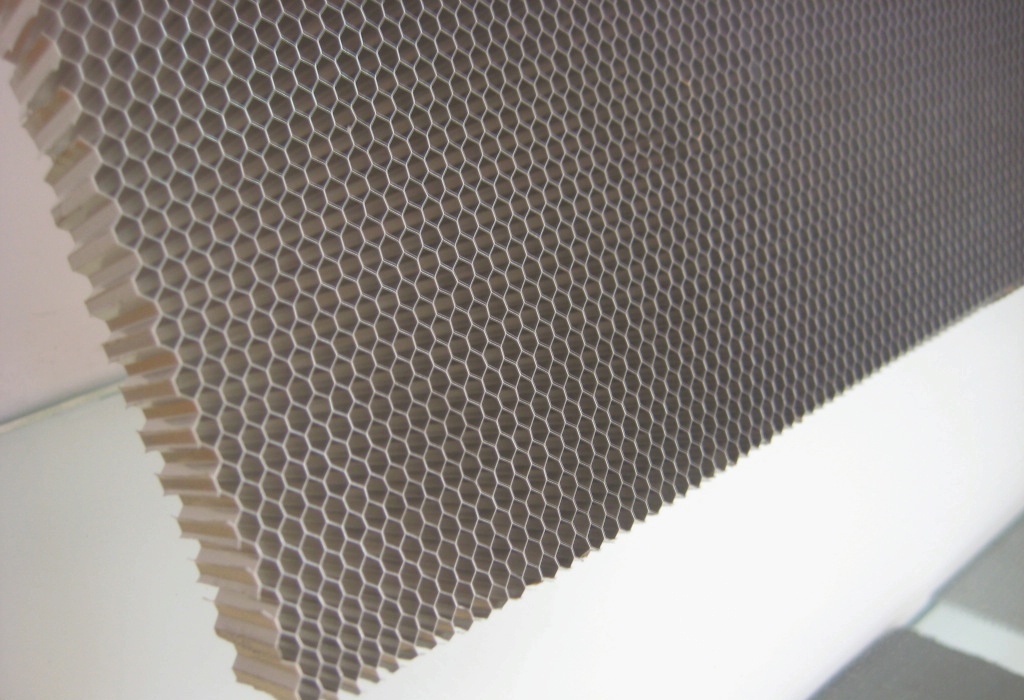

Honeycomb aluminum plate is a honeycomb sandwich plate with honeycomb structure as the core layer, which is inspired by natural hexagonal honeycomb. The honeycomb aluminum plate made of aluminum alloy not only has the lightest quality among other materials of the same volume due to its unique structure, but also has good rigidity and overall stability, and also has sound insulation and heat insulation performance.

Read more

Aluminum honeycomb panel is a new type of material, and there are many varieties, so it has not yet found a unified classification method, which is generally classified according to its product function, use and surface decoration effect.

Read more

Deepen the three-dimensional model of the roof (curtain wall) system. The deepening process of honeycomb aluminum plate is to analyze and simulate each plate through special computer design software to determine the processing and manufacturing method of each plate, because all plates are distorted and need to be produced in large quantities on a large scale.

Read more