China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

1. Effect of Adhesive on Peel Strength of Aluminum Honeycomb Panel (1) The adhesive strength of aluminum honeycomb panel produced by polyurethane and epoxy resin room temperature curing adhesive is low. The 180 peel strength measured for aluminum honeycomb panel with honeycomb core side length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm. The adhesion and weather resistance of this aluminum honeycomb panel are poor, and the adhesion performance is greatly reduced after 1 year of use. The aluminum honeycomb panels produced by this process are not suitable for outdoor use, but can be used for indoor decorative partitions. (2) The adhesive strength of aluminum honeycomb panel produced by epoxy film process is low. The 180 peel strength measured for aluminum honeycomb panel with honeycomb core edge length of 4mm, panel thickness of 1mm and total thickness of 10mm is about 4N/mm. However, its adhesive performance is good in weather resistance, and its peel strength decreases little after 1 year of use. The disadvantage is that the bonding layer of the aluminum honeycomb panel is brittle, and the aluminum honeycomb panel will be layered after long-term vibration. (3) The bonding strength of the aluminum honeycomb panel produced by the thermoplastic film continuous composite process is 3-5 times that of the aluminum honeycomb panel produced by the first two processes. For the regular hexagonal honeycomb core

Read more

Stainless steel aluminum honeycomb panel? project will be in service for many years. This durability means playing a major role in the development of a more sustainable society: improving energy efficiency, reducing pollution, and reducing the use of materials.

Read more

When it comes to aluminum honeycomb, I don\'t think people in the industry will know that the origin of aluminum honeycomb panels comes from aluminum veneer. Scientists have found that the nest made by bees is a hexagonal six-sided object, which is stronger than any other shape. This multi-wall arrangement structure and network structure can disperse the external force from all parties, making the honeycomb structure resistant to extrusion force, much higher than any round or square structure. Honeycomb structure to people\'s inspiration: even if the use of very thin materials, as long as it is made into a honeycomb shape, it can withstand strong pressure, it is this revelation, aluminum honeycomb plate material began to appear. At first, aluminum veneer was used for decoration. Later, it was found that aluminum honeycomb panels would be more decorative and functional than aluminum veneer, and this emerging industry officially grew up. But the market of aluminum honeycomb panel is really qualified aluminum honeycomb panel? At present, there is no national standard version of the implementation of aluminum honeycomb panel. The quality of the industry is uneven, very chaotic, with the second best comparison

Read more

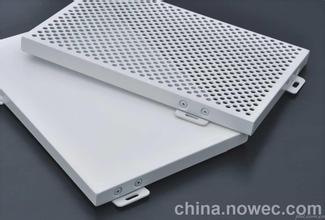

With the rapid rise of aluminum veneer ceiling, it has become a rising star in the building materials industry, attracting more and more attention from building materials industry, and consumers have gradually accepted this new product. The production and sales of aluminum veneer ceiling have sprung up and developed rapidly. The development of the market has not fundamentally solved the development problems of enterprises in the single-board tooling ceiling industry. With the increasingly fierce competition among enterprises, such as high production costs, lack of financial support, slow progress in engineering convenience, difficulties in cross-industry cooperation, insufficient market promotion, flashy functions, complicated installation and debugging, etc. have become the development of large-scale industrialization in the industry. Kaimai Metal Building Materials Aluminum Industry has focused on solving the problem fundamentally since the birth of the aluminum veneer ceiling industry, and invested a large amount of research and development funds and production equipment. The industry\'s first fully automatic aluminum honeycomb panel line was born in Kaimai Metal Building Materials. After that, aluminum plate roller coating line, UV production line, aluminum oxidation line, LED light guide plate forming and printing production line were added one after another. Now Kaimai metal building materials have been

Read more

What is corrugated board, I believe everyone must be relatively unfamiliar, corrugated board is aluminum veneer combined with a layer of corrugated core, compared with aluminum veneer built-in corrugated core effect is not a little bit, the biggest problem of aluminum veneer is that the flatness is not high, and easy to crash, if the built-in corrugated core will play a great role is to greatly improve the flatness, especially if the ceiling with aluminum veneer corrugated board flatness will be very low, and obvious effect.

Read more

Looking at the domestic curtain wall aluminum veneer market, due to the blind expansion and competition of manufacturers, the current aluminum veneer market has entered the era of price competition. In such a market, some merchants will produce inferior aluminum veneer, often replacing fluorocarbon aluminum veneer with polyester aluminum veneer. Ordinary people cannot see any problem with naked eyes. Today, Xiao Bian will share with you how to identify the authenticity of fluorocarbon aluminum veneer.

Read more