China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel refers to the processing of building decoration materials formed by fluorocarbon spraying technology after chromium treatment.

Read more

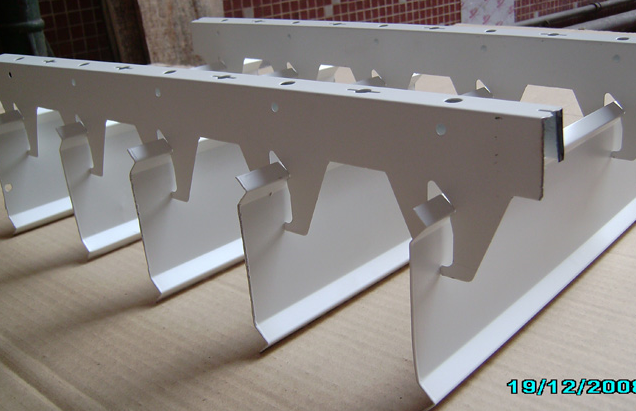

Our construction unit for dry hanging of aluminum veneer has compiled the construction process and plan as follows: 1. Construction process 2. Operation process 2.1 Construction preparation (1) Design drawings and on-site measured dimensions to determine the installation position of aluminum veneer support frame. (2) According to the control axis and horizontal elevation line, the reference line for aluminum veneer installation (including vertical and horizontal axis and level line) is popped up. (3) Install the connecting pieces of the fixed frame. The horizontal and vertical members of the skeleton are fixed to the structure through connecting pieces, while the connecting pieces are fixed to the structure by welding. (4) The fixed skeleton and the installation position of the skeleton should be accurate and the combination should be firm. 2.2. Installation of frame keel 1. According to the specification requirements of aluminum veneer, the specific position of horizontal and vertical frame keel shall be determined. High-rise buildings need to use theodolite control correction, requiring horizontal and vertical. 2. On both sides of the keel of the vertical frame, drive steel expansion bolts according to the middle distance of 450-500mm to fix the L30x30x3mm galvanized angle steel on it, and the position shall be accurate. 3. According to the construction drawing, the vertical frame keel adopts 40x 20x 2mm hot-dip galvanized square pipe, and the vertical frame keel is fully welded and fixed on the steel angle code. Transverse Frame Keel L

Read more

At present, as the requirements of the acoustic performance of the occasion, such as hall, hall, hall, field decorative sound-absorbing panels, aluminum honeycomb panels and other sound-absorbing materials such as sound-absorbing paper, glass fiber cotton and other functional combination, play their respective advantages, can play a better sound-absorbing effect.

Read more

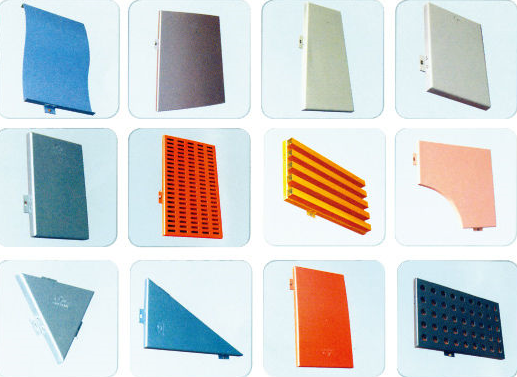

Material and structure of aluminum veneer curtain wall: aluminum veneer curtain wall is made of high-quality and high-strength aluminum alloy plate, and its common thickness is 1.5mm, 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm, model 3003, state H24. The maximum size of conventional materials is 1220MM x 2440MM. Its structure is mainly composed of panels, stiffeners and corner codes. The corner code can be directly bent and stamped from the panel, or riveted on the small edge of the panel. The reinforcement is connected with the electric welding screws behind the plate surface, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, and ensuring the flatness and wind resistance and earthquake resistance in long-term use. If sound insulation is required, high-efficiency sound insulation materials can be installed on the inside of the aluminum plate. Surface treatment of aluminum veneer curtain wall The surface of aluminum veneer curtain wall is generally treated with fluorocarbon spraying after pre-treatment such as chromating. Fluorocarbon paint topcoats and varnishes of polyvinylidene fluoride resin (KANAR500). Generally divided into two coated, three coated or four coated. Fluorocarbon coating has excellent corrosion resistance and weather resistance, can resist acid rain, salt spray and various air

Read more

If the office site is selected, the decoration must be indispensable. So, what kind of ceiling is suitable for office decoration?

Read more

Honeycomb aluminum building energy saving refers to the energy consumption of saving heating, air conditioning and refrigeration, lighting and indoor air purification, temperature adjustment and improvement of indoor environment quality

Read more