China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

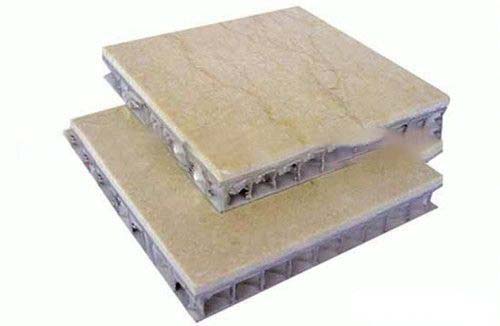

Stone aluminum honeycomb panel manufacturersIs a combination of aviation industry composite honeycomb panel technology and the development of metal composite panel Products. The product uses a honeycomb sandwich structure, that is, a high-strength alloy aluminum plate coated with a decorative coating with excellent weather resistance is used as the surface, and the bottom plate and the aluminum honeycomb core are manufactured by high temperature and high pressure compounding.

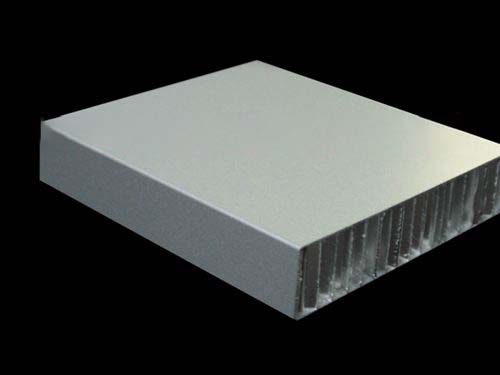

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

In addition, the panel in addition to the use of aluminum alloy, but also according to customer needs to choose other materials, such as: copper, zinc, stainless steel, pure titanium, fireproof board, marble, aluminum-plastic board and so on.

Quality Supervision of Aluminum Honeycomb Panel

1. quality inspection personnel shall measure the plate cut by the CNC plate shearing machine according to the drawings to check whether the size is consistent with the opening size of the drawings.

2. quality inspection personnel to check whether the size of the opening angle is consistent with the drawing.

3. quality inspection personnel to inspect the formed board and check whether the folding height and the light size of the board surface are consistent with the drawings.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

4. quality inspection personnel to the composite honeycomb board inspection, check whether there is glue on the board surface, whether there is a large gap between the panel and the bottom plate.

The 5. quality inspection personnel shall inspect the assembled honeycomb panel, and the stone aluminum honeycomb panel manufacturer shall check whether the installation position of the angle code is correct and whether there are scratches and dents on the panel surface.

Stone Honeycomb PanelFeatures:

◆ can use a variety of natural stone varieties;

◆ More than 80% lighter than traditional stone slabs;

◆ The impact strength is more than five times larger than that of 3.0cm thick traditional stone;

◆ Can be used in outdoor, indoor, elevator and furniture decoration;

◆ can be prefabricated into curtain wall unit, quick and easy installation;

Good water resistance can prevent water infiltration;

Low installation cost, short cycle of stone aluminum honeycomb panel manufacturers;

It has been tested by the natural environment for 30 years;

◆ Surface stone treatment can be a mirror, matte surface, washing surface, fire surface, litchi surface, sandblasting surface, planer surface and other options;

Recommended:Maintenance method of composite floor buckle