China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

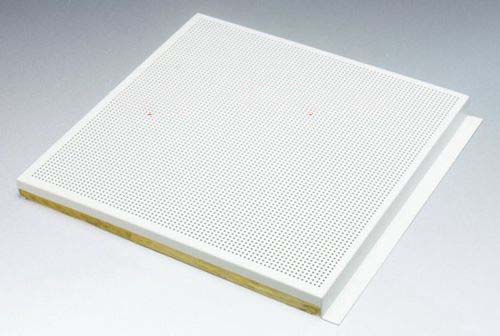

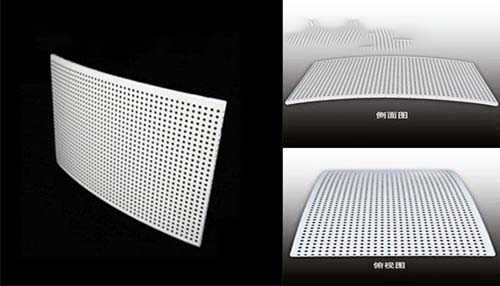

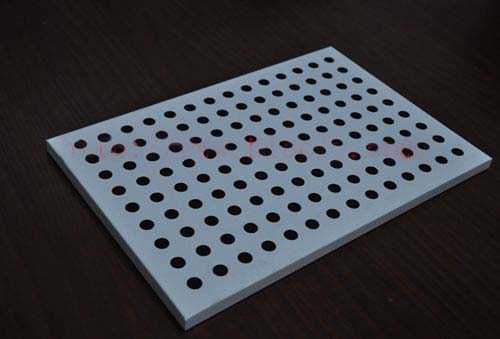

aluminum honeycomb panel punchingIt is a small hole that is punched out according to a certain rule on the surface of the aluminum honeycomb panel. It is not only beautiful and generous, but also the sound-absorbing paper hidden inside has a very good attraction effect. It is suitable for conference rooms, auditoriums and other occasions.

Features: The center is aluminum hexagonal honeycomb with low density (about 3~7kg per square meter), 1/5 of the weight of wood with the same thickness and area, 1/6 of glass and 1/7 of aluminum, greatly reducing the building load and cost. As the middle interlayer contains a large amount of air, it can make sound insulation (air sound insulation can reach 30dB) and heat insulation (thermal resistance can reach 0.02(㎡?K/W)).

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Aluminum honeycomb panel punching without combustible substances, fire rating reached B1, waterproof, moisture-proof, no harmful gas release, unit mass specific strength, high specific rigidity (structural rigidity is 1.7 times of rib type), not easy to deform, completely overcome the deformation of other decorative panels in a single large area, intermediate collapse and other shortcomings of convenient processing and application, can be arbitrarily cut and folded.

The surface fluorocarbon coating can guarantee the product life of more than 30 years. The surface of aluminum honeycomb panel has extremely high flatness and good seismic performance, which is only 1/8 of the specific gravity of glass curtain wall. The load of 22mm thick standard parts can reach more than 700kg force when it is simply supported at 1 meter and the deflection is 10mm.

aluminum honeycomb panelMain features of punching:

1, light, low installation load;

2, high flatness, not easy to deformation, high safety factor;

3. It has very good sound absorption performance.

4, more ornamental.

The punching of aluminum honeycomb panel can be designed with different perforation rates according to the indoor acoustic design, and the sound absorption coefficient of the combined structure can be controlled within a certain range, which not only achieves the design effect, but also can reasonably control the cost.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

By controlling the perforation aperture and hole spacing, the perforation rate can be changed according to the customer\'s use requirements. the maximum perforation rate is less than 30%. the aperture is generally selected from #2.0, #2.5, #3.0 and other specifications. the perforation requirements for the back plate are the same as those for the panel. the sound-absorbing cloth is made of non-woven sound-absorbing cloth and other sound-absorbing materials made by kedebao of Germany.

Recommended:Installation skills of sound-absorbing aluminum honeycomb panel