China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

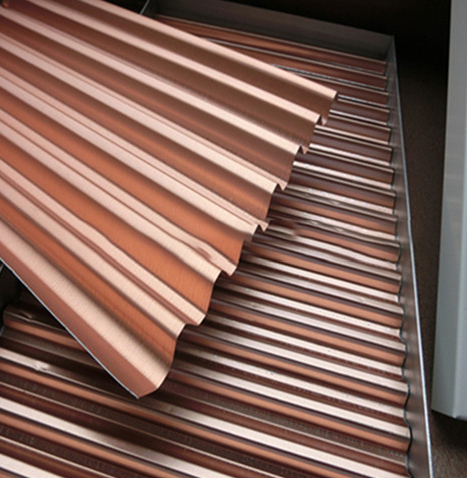

corrugated composite aluminum plateIt is a new type of composite aluminum plate curtain wall material made of 0.6-0.8mm panel, 0.4mm bottom plate, and 0.2mm corrugated aluminum plate in the middle. The surface of the corrugated core material is coated with thermosetting epoxy resin adhesive, and the aluminum plate product is compounded by heating and pressing. Its compounding method is similar to the form of corrugated carton board.

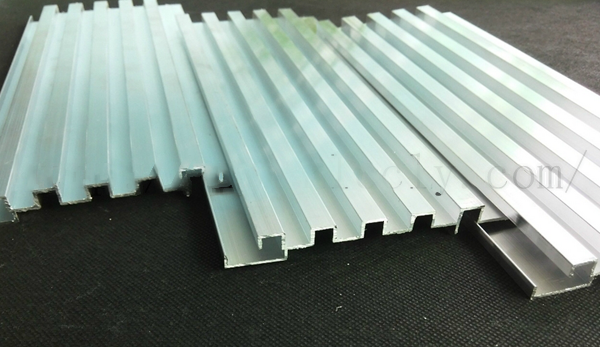

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Corrugated aluminum plate is also known as pressure aluminum plate, wave aluminum plate or aluminum tile. It is one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

Corrugated composite aluminum plate has the characteristics of light weight, high strength, rich color, convenient construction, seismic, fireproof, rainproof, long life, maintenance-free, etc., and has been widely used. Now there have been many plastic extrusion corrugated board, corrugated aluminum, corrugated aluminum, there are transparent, there are opaque and colored, as well as multi-layer composite hollow. Because of its good plasticity, it can better adapt to the requirements of various architectural shapes, but compared with the service life, aesthetic degree and durability and other performance color steel corrugated board is better.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The corrugated composite aluminum plate includes a unit corrugated cardboard layer and a face paper layer. The composite cardboard is made of multiple strips of unit corrugated cardboard after slitting, cutting, turning, and standing up. The unit corrugated cardboard is composed of corrugated paper and box board paper. The characteristic is that the box board paper and corrugated paper of the unit corrugated cardboard are arranged alternately, and there are at least three layers after the setting of bonding.

stainless steel honeycomb plateEasy and fast installation.

This corrugated composite aluminum plate is made of composite cardboard made of unit corrugated cardboard, and its thickness can be 10 Millimeters or less, the compressive strength is more than three times that of corrugated cardboard in the prior art, and it is easy to cut in the process of manufacturing composite cardboard, and it is not easy to break when cut into strips, which increases the strength during slitting.

Recommended:How about the performance of stone honeycomb aluminum plate