China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

aluminum honeycomb panelThe panel is made of high-quality 3003H24 alloy aluminum plate or 5052AH14 high-manganese alloy aluminum plate as the base material. The thickness of the panel is 0.8~1.5mm fluorocarbon roll-coated plate or light-resistant baking paint. The core material is hexagonal 3003 aluminum honeycomb core.

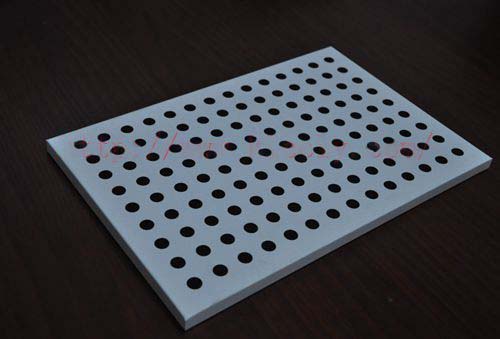

The aluminum foil adopts roll forming technology to complete the forming of the front and back skins; there are small holes on the honeycomb aluminum skin, so that the gas in the plate can flow freely; the sliding installation buckle system will not cause structural deformation during thermal expansion and contraction, so it can Ensure extremely high flatness

。

。

Guangdong aluminum honeycomb panelIs based on aluminum metal plate, with ordinary aluminum veneer antibacterial, anti-corrosion, long service life characteristics, because of its special design it sound insulation, seismic, moisture-proof effect is also very prominent.

The inner layer is a special hexagonal honeycomb, which is called \'aluminum honeycomb panel\' because of its honeycomb shape \'.

Aluminum honeycomb panels are generally made of fluorocarbon roll coated aluminum panels. The most important point of fluorocarbon roll-coated aluminum plate is the use of a continuous roller coating process, the aluminum plate is painted at one time to ensure that the product has no color difference, good coating flatness and reliable quality. At the same time, it can keep the color of the outer wall of the building bright for a long time. After long-term sun and rain or industrial waste gas pollution, it is obvious that the roller coated board is cleaner and brighter than the spraying board, and has good adhesion and weather resistance. It is the first-class material recognized by the world\'s builders.

The aluminum honeycomb core is made of multiple layers of aluminum foil bonded together and then expanded into a regular honeycomb shape. And suitable for high quality honeycomb core face material paste and other purposes.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Aluminum honeycomb panel has excellent properties such as light weight, sound insulation, fire prevention, non-fragile, strong rigidity, and environmental protection. Widely used in building curtain wall, and indoor and outdoor decoration, luxury car ship interior, high-speed train, etc.

Aluminum honeycomb panel: aviation technology used in civil construction, vehicle and ship decoration. It is the application of aviation and aerospace materials in the field of civil construction.

After the surface is treated with fluorocarbon resin with strong corrosion resistance, it can be widely used in the decoration of curtain walls, roofs, large facade signs and interior walls of buildings. The front aluminum plate of aluminum honeycomb panel shall conform to E. C. C. A. quality standard PVDF fluorocarbon paint, divided into ordinary color and metallic color. Therefore, the surface also has excellent weather resistance.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Innovations that follow natural Products often imitate the structure and form of nature. Human inventions and creations are all inspired by nature and adapt to the requirements of nature. Aluminum honeycomb panel with its light weight, high strength, stiffness and many other advantages, has been widely used in building exterior decoration.

Recommended:Maintenance method of composite floor buckle