China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Laying composite floor metal buckle stripDue to factors such as productivity, manufacturability, and safety, the most common shapes are round, hexagonal, unequal, equilateral, etc. The most common three-dimensional shapes are spherical, hemispherical, floating and other three-dimensional shapes. The most common local modeling is to model individual and all local details on the basis of shape modeling, such as adding Arabic numerals, English letters, plane patterns, animals, figures, flowers, registered trademarks and patterns, etc.

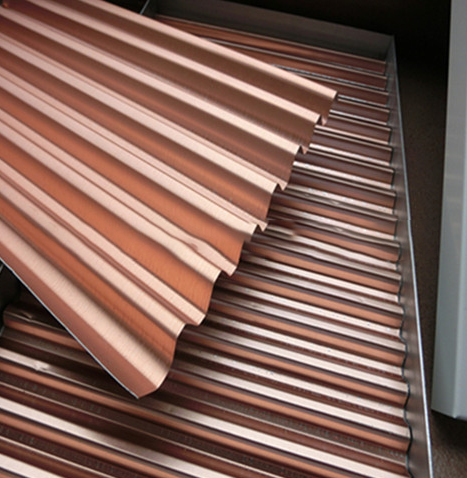

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Classification of metal buckle strip when laying composite floor:

1. skirting board: used for wall, covering the floor and pressing the floor, beautifying.

2. door buckle: where is the door, that is to say, the connection between the two areas also plays a role in shielding.

3. right angle: where is the floor paved in the wardrobe? there is a gap that is not good-looking. under the cover of right angle, it is divided into PVC and metal.

stainless steel honeycomb plateEasy and fast installation.

At present, many businesses have introduced all-inclusive accessories to avoid the above-mentioned consumption traps. Laying composite floor metal buckle strip this situation will also choose to use buckle strip. Because the cost of a buckle is very low. For thousands of floors the total cost is negligible. The saving of a buckle increases the risk of floor bulging due to thermal expansion and contraction.

Laying composite floor metal buckle strip use method:

1. Use a dry cloth or sandpaper to remove dust, oil, rust, etc. from the contact surface, and then wipe it with a cleaning agent such as acetone or trichloroethylene to clean the surface.

2. Unscrew the front cover, and stir agent B of agent A in the weight ratio described above to use (A:B = 2:1); In order to ensure the effect of use, vacuum can also be used again.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

3. Note that it must be used up within the operating time, otherwise it will solidify, resulting in waste of materials, and the highest strength can be obtained after 24 hours.

4. After gluing. Room temperature 2~6 hours curing 40 degrees ~ 50 degrees 1~3 hours curing; glue 24 hours after use; ten days after the better adhesion. Cold and humid days, need 15~25 degrees room temperature bonding as well.

Recommended:Precautions for installation of aluminum honeycomb panel