China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

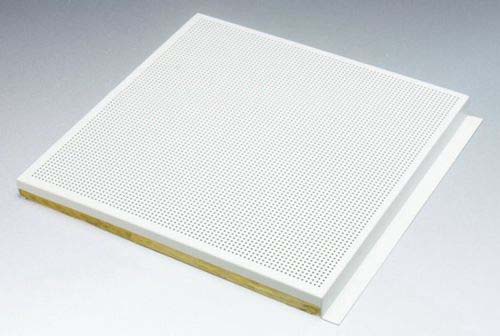

Composite strip aluminum gussetThe board surface is flat, the ridges are clear, and the ceiling system reflects the appearance effect of neat, generous, rich and elegant, and wide vision. The aluminum gusset plate has the advantages of flame retardant, anti-corrosion and moisture-proof, and is convenient to assemble and disassemble. Each plate can be disassembled independently, which is convenient for construction and maintenance.

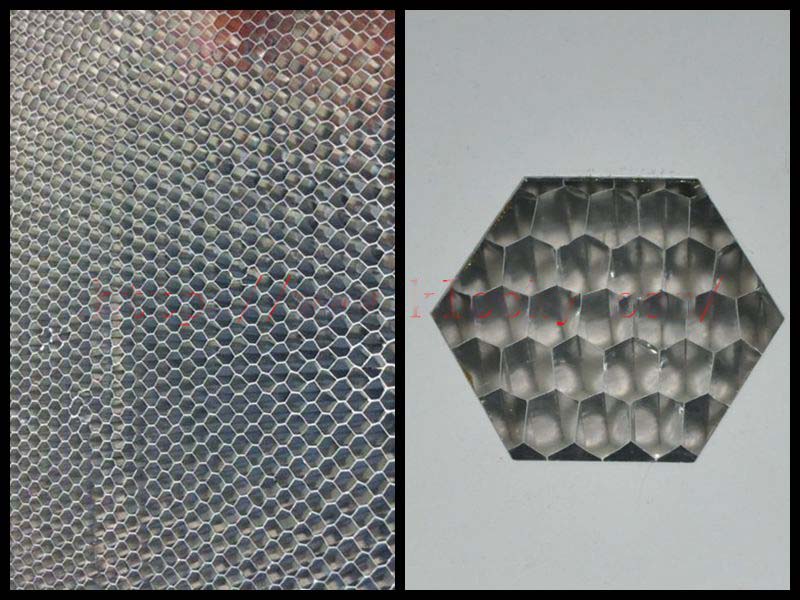

Honeycomb aluminum plateIt is a composite material with large surface formed by hot pressing of high-grade aluminum alloy panel, back plate and aluminum honeycomb core material. The product specifications are various, and the surface can be embossed, mirror, embossed, wire drawing, electroplating, anodizing, matte, bright light and metallic color, etc., which can meet the application requirements of various places.

Composite strip aluminum gusset plate is widely used in outdoor curtain wall decoration and indoor high-grade home decoration, advertising decoration and so on because of its many colors, strong decoration and good weather resistance.

As an important material of ceiling, composite strip aluminum gusset plate is more and more widely used in decoration. The aluminum gusset plate Products on the market are mixed, which is a test of consumers\' ability to distinguish. The following teach you to hold you to buy a satisfactory aluminum gusset plate.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, tunnel corridors, etc.

The surface treatment of the composite strip aluminum gusset plate can be divided into several forms such as spraying, rolling, and laminating. Among them, the spraying board has short service life and is prone to color difference. The surface of the roller coated board is uniform and smooth, without leakage coating, shrinkage cavity, scratch, peeling and other characteristics. The surface of the laminating board is a layer of PVC film, which has the advantages of firm surface adhesion, no wrinkling, scratch, falling off, leakage paste and the like.

stainless steel honeycomb plateEasy and fast installation.

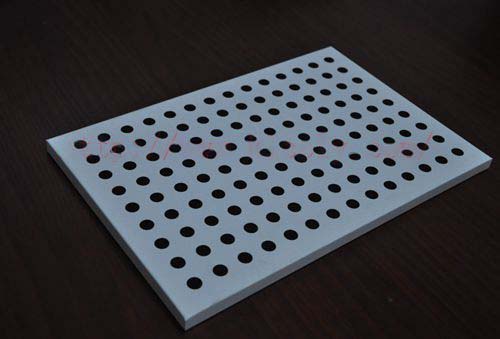

The composite strip aluminum gusset plate is made of high-grade aluminum alloy as the main material, and the panels are processed and formed by the flat stretching and molding processes patented by our company, which has the characteristics of high processing accuracy, stable appearance and high surface flatness. The aluminum gusset has many perforated styles and splicing methods. The rectangular or square panels are arranged and combined to convey a concise and generous visual effect, and it is also convenient for each project to achieve its own unique style through different arrangements.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

The thickness of the surface coating of the composite strip aluminum gusset plate or the thickness of the film, the thickness of the substrate. The thickness of the better aluminum gusset plate coating is only between 0.02 and 0.03mmz, and the thickness of the film is usually less than 0.15mm. The residual aluminum gusset plate is often used on the aluminum substrate and the aluminum gusset plate coating or film. Usually, the thickness of the aluminum substrate is reduced, and several more coatings are sprayed on the aluminum substrate or very thick film is selected. Even some aluminum gusset plates in the shopping mall are only 0.15mm, but the film is 0.4mm. Aluminum gusset plate substrate is too thin, coating or film too thick will also reduce the function of aluminum gusset plate.

Recommended:aluminum alloy corrugated board