China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Honeycomb Aluminum Panel InstallationIt should be placed in place according to the plate number on the plate distribution diagram, the angle codes installed at the gelatin seam parts should be assembled, and check whether the angle codes of the two adjacent plates are staggered, try to assemble and check their levelness and verticality, then assemble with stainless steel bolts, try to fix them on the main and auxiliary keels, adjust the horizontal and vertical seam clearance to meet the requirements, and then fix them. In the hidden joint position, use hidden joint pressure plate to fix, check the two gaps, honeycomb aluminum plate installation to ensure consistency, specific requirements should ensure honeycomb aluminum plate left and right, up and down deviation of ± 1.5mm, pay attention to hidden joint pressure plate should be sealed with sealant, glue seam should be greater than 5mm and should ensure its tightness.

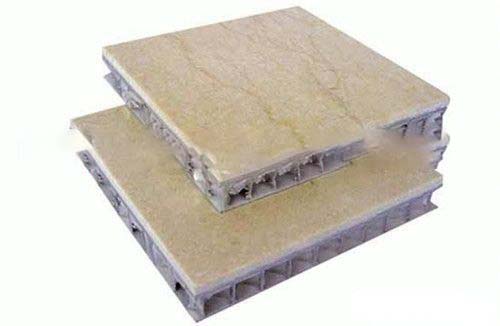

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, tunnel corridors, etc.

Honeycomb aluminum plateThe outer aluminum sheet and the middle honeycomb structure are bonded by pressure, so that the overall stiffness is large, and it can withstand large wind load and impact force.

Because of its structure by the inner and outer two layers of 1.0mm thick aluminum plate and the middle of the aluminum honeycomb bonding, so that it compared to the same stiffness of the aluminum veneer lighter weight, can greatly reduce the load of the building.

Since the air layer between the two panels is divided into many closed gaps by the honeycomb, the installation of the honeycomb aluminum plate greatly restricts the transmission of sound and heat, making it have better sound insulation and heat insulation performance.

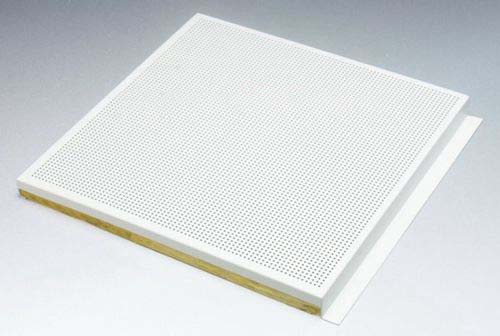

stainless steel honeycomb plateEasy and fast installation.

Honeycomb aluminum sheet itself does not emit any gas, and its anti-dirt easy to clean can be recycled.

Using a unique hidden glue seam cover strip system, the seam is coated with weather-resistant glue, and the outer buckle decorative strip, which is beautiful and waterproof.

Easy to use and install, can be arbitrary cutting, folding, made of various types of special-shaped plate.

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

The panel adopts fluorocarbon spraying process, which can guarantee no discoloration for 30 years, and there are many colors to choose from.

Honeycomb aluminum sheet is a new type of composite material, which is composed of upper and lower aluminum sheets and honeycomb core through adhesive. The panel is usually sprayed with fluorocarbon paint or polyester paint. The fluorocarbon coating is widely used outdoors due to its good weather resistance and self-cleaning, while the polyester coating is mostly used indoors.

Recommended:What are the advantages of composite strip aluminum gusset plate