China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Composite honeycomb aluminum sheet stoneWith the world\'s population growth and economic development, the resource consumption and environmental effects of buildings and their operation have increasingly significant impacts on the global resources and environment. Reducing building energy consumption and pollution emissions, saving resources, protecting the environment, and realizing the harmonious coexistence of buildings and nature are common issues facing the world.

Under this premise, the ultra-thin stone honeycomb composite board came into being. It is a new type of building material with better impact resistance than ordinary natural stone. It is only 8-11kg per square meter, which is 1/7 of the weight of ordinary natural stone, but its compressive strength is 3-5 times. It completely overcomes the defects of natural stone such as heavy weight and fragility, and provides a new generation of building materials with more excellent performance and wider application fields.

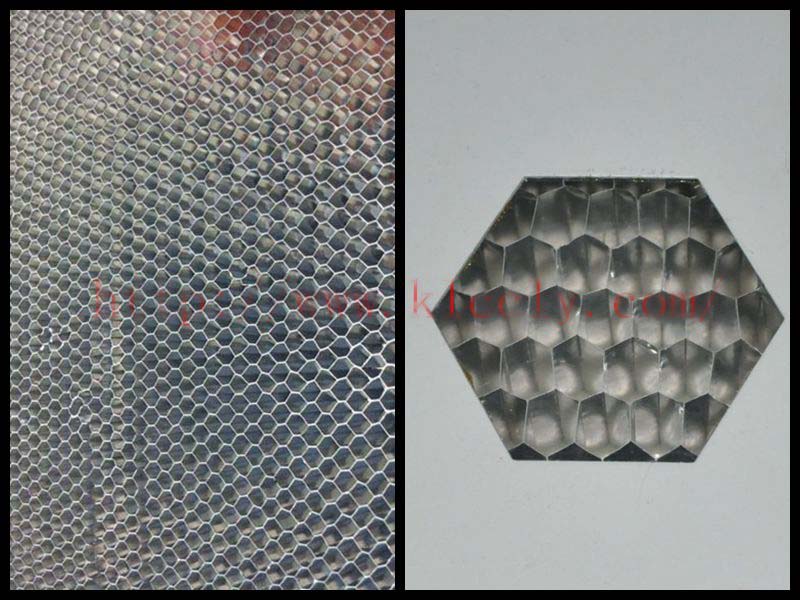

Honeycomb aluminum plateIt is a composite material with large surface formed by hot pressing of high-grade aluminum alloy panel, back plate and aluminum honeycomb core material. The product specifications are various, and the surface can be embossed, mirror, embossed, wire drawing, electroplating, anodizing, matte, bright light and metallic color, etc., which can meet the application requirements of various places.

Because the marble composite board is cut into 3 or 4 pieces with 1m2 of the original board (full-body board) and becomes 3m2 or 4m2. The 3, 4m2 pattern and color is almost 100% the same, so it is easier to ensure the consistency of the color and pattern when used in large areas.

The ultimate state bending stress when the stone panel of the stone honeycomb curtain wall cracks or breaks under bending tension is taken as the bending strength value of the whole plate, and the bending stress when the whole plate is bent and yielded is not taken as the bending strength value.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Because when the stone cracks or breaks, the plate can still be in normal working condition and has not completely lost its basic function, but due to the existence of stone cracks, the composite honeycomb aluminum plate stone can cause rain or moisture to directly penetrate into the adhesive of the adhesive layer, thus accelerating the aging process of the adhesive and reducing the durability of the plate, therefore, the bending stress when the stone slab is cracked or broken should be used as the bending strength of the stone honeycomb panel.

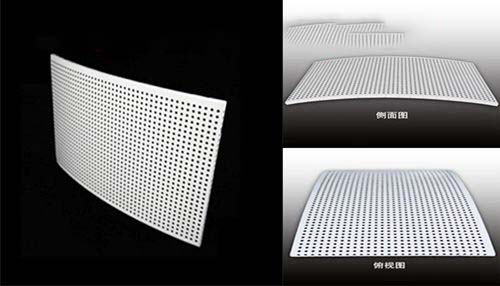

Aluminum veneer is a single-layer product, the processing is relatively simple, the modeling ability is strong, but the accuracy is poor; the honeycomb panel is a composite product, the processing speed and ability are weak, but the accuracy is guaranteed.

stainless steel honeycomb plateEasy and fast installation.

The box-type honeycomb aluminum plate adopts a buckle cover system. The composite honeycomb aluminum plate stone has two systems to choose from: exposed glue seam and hidden glue seam. The system fully considers the influence of thermal expansion and contraction on the plate surface itself. The four directions of the plate surface can expand and contract freely, effectively avoiding the influence of temperature stress on the flatness of the plate surface.

Recommended:Dimensions of Arc Aluminum Honeycomb Panel