China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Honeycomb aluminum plate installation nodeWith the advantages of light weight and high strength, it has been widely used. As early as 50 years, aluminum honeycomb panels have been used in aviation and aerospace fields. This sandwich structure is commonly used in aircraft for radomes, all movable control surfaces, ailerons, floors, bulkheads, ceilings, stowage bins, etc.

With the progress of science and technology, mature technology, combined with the single construction Products, large quantities and other characteristics, the cost of aluminum honeycomb panels has been greatly reduced before it began to be applied in the construction field. By the mid-1990s, it was mainly used as a decorative curtain wall panel inside and outside the building, and has achieved unexpected results in the market so far.

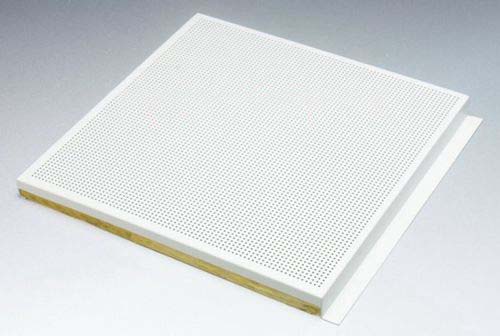

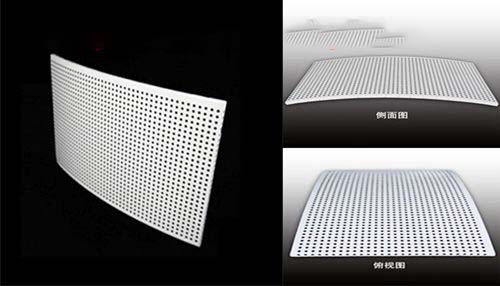

Aluminum honeycomb panel has the characteristics of light weight, high strength, especially high stiffness. The stiffness of ordinary aluminum-plastic panel and aluminum veneer can not be compared with it. The board surface is particularly flat, as the outer decorative metal curtain wall panel, its decorative effect is particularly prominent.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Honeycomb aluminum plateThe installation node has a series of excellent properties such as zero color difference, sound insulation, heat insulation, non-combustible, easy processing on site, etc., which overcomes the defects of aluminum-plastic panels and aluminum veneer, and is the most ideal building material for exterior wall decoration. It is more and more widely used in metal curtain walls.

The verticality of the structural column is relatively positive, hang the vertical line on the keel installation axis, measure the upper and lower points with an angle ruler, record the data, and enlarge the average value by 10mm.

Mark the axis position on the floor with red and blue pencil, draw it out with 90 ° extension lead wire of angle ruler, and determine the relative position of keel axis with the same positive error as above.

stainless steel honeycomb plateEasy and fast installation.

Honeycomb aluminum plate installation node measurement and setting out measurement and setting out is the most precise process in ceiling engineering, which plays an important role in controlling the flatness of the ceiling. The measurement and setting out shall comply with the overall measurement and control procedure before the local measurement and control procedure, and the horizontal control line of the ceiling keel shall be released by theodolite according to the original structural axis.

According to the data required by the standard, the arch control line of the suspended ceiling keel is provided on the basis of the elliptical curve arch of the suspended ceiling. The measurement and setting-out requires scientific method, orderly calculation, step-by-step verification and reliable results.

Recommended:Installation method of composite honeycomb aluminum plate stone