China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Galvanized zinc corrugated boardIt is composed of aluminum-zinc alloy structure, which is composed of 55% aluminum, 43% zinc and 2% silicon solidified at a high temperature of 600 ℃. Its entire structure is composed of aluminum-iron-silicon-zinc, forming a dense quaternary crystal alloy.

Galvanized corrugated board is widely used in building materials, home appliances, automobiles, environment, machinery, ships and many other fields of an alloy coating steel plate.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Galvanized corrugated board has good heat resistance and can withstand high temperatures of more than 300 degrees Celsius. It is very similar to the high temperature oxidation resistance of aluminized steel plate. It is often used in chimney pipes, ovens, illuminators and solar lampshades.

Because the steel plate is damp, it will produce oxidation and rust, it must be added to the surface. On the anti-corrosion protection layer, the commonly used anti-corrosion coating is divided into hot-dip galvanized Zn and hot-dip aluminum-zinc alloy Al-Zn (aluminum-zinc alloy composition is 53% aluminum, 43.5 zinc and 1.5 silicon, referred to as 55% Al-Zn). Data show that the comprehensive anti-corrosion ability of 55% aluminum and zinc is 4 times of the same thickness of zinc plating.

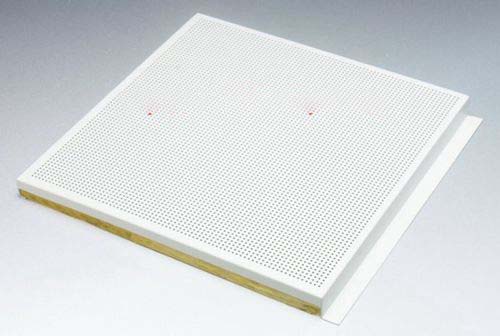

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Application of aluminized zinc corrugated board

Buildings: roofs, walls, garages, soundproof walls, pipes and modular houses, etc.

Automobile: muffler, exhaust pipe, wiper accessories, fuel tank, truck box, etc.

Home appliances: refrigerator backplane, gas stove, air conditioner, electronic microwave oven, LCD frame, CRT explosion-proof belt, LED backlight, electrical cabinet, etc.

Made of high-tech aluminum-zinc steel plate, even at 315 ℃ lasting use will not fade, because of its excellent quality is more and more widely used in indoor and outdoor decoration materials, steel structure roof and maintenance system, electrical, electronic, ventilation, machinery manufacturing, drainage system, etc.

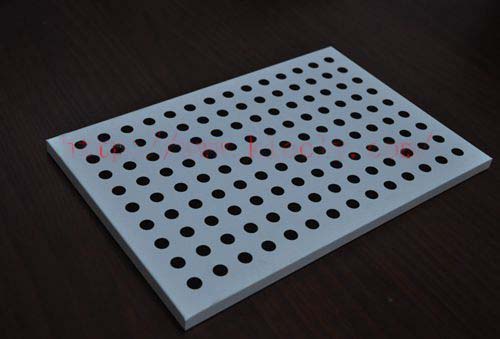

Mirror honeycomb panelThe appearance is straight, the color is diverse, the color is uniform and stable.

Precautions for use

Custody: It should be kept in warehouses and other rooms, kept dry and ventilated, and not kept in acidic climate for a long time. Outdoor storage to prevent rain, to avoid condensation caused by oxidation spots.

Transportation: avoid external impact, use SKID to support steel coils on transportation tools, reduce stacking, and take rainproof measures.

Recommended:What is the density of honeycomb aluminum plate