China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

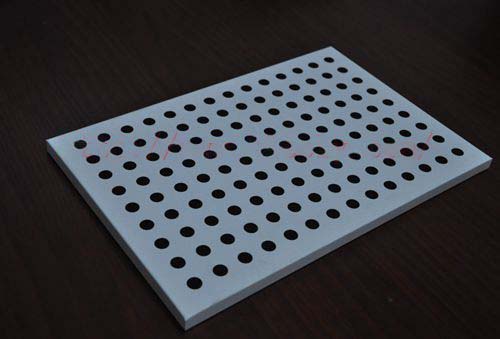

Honeycomb aluminum plate densityIs a combination of aviation industry composite honeycomb panel technology and the development of metal composite panel Products. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Honeycomb aluminum plateIt is a composite material with large surface formed by hot pressing of high-grade aluminum alloy panel, back plate and aluminum honeycomb core material. The product specifications are various, and the surface can be embossed, mirror, embossed, wire drawing, electroplating, anodizing, matte, bright light and metallic color, etc., which can meet the application requirements of various places.

Honeycomb aluminum Products are selected from the company\'s unified standard pre-roller coated high-grade aluminum alloy coil, combined with a variety of production processes refined.

honeycomb composite technology

(1) The honeycomb aluminum plate is derived from the scientific and technological achievements of modern aviation, and is lighter in weight, but the strength of the plate is higher.

(2) The use of high-temperature composite and panel hot pressing technology to ensure the integrity, strength and flatness of the board.

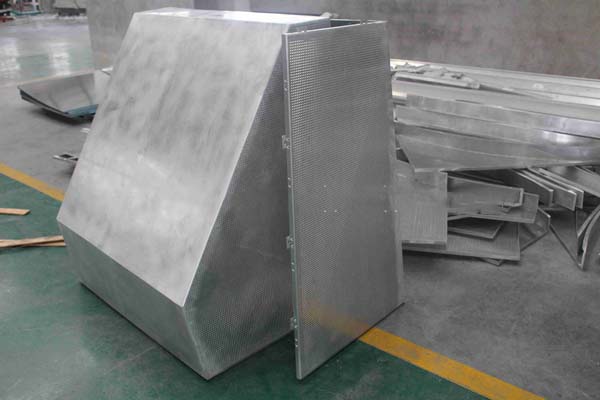

At the position of hidden seam, the density of honeycomb aluminum plate is fixed by hidden seam pressing plate. Check the two gaps to ensure consistency. The specific requirements shall ensure that the deviation of the honeycomb aluminum plate from left to right and from top to bottom is ± 1.5mm. Note that the joint of hidden seam pressing plate shall be sealed with sealant. The glue seam shall be greater than 5mm and its tightness shall be ensured.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

The installation of honeycomb aluminum plate shall be placed in place according to the plate number on the plate allocation diagram. The installation angle code of the honeycomb aluminum plate density gelatin seam part shall be assembled, and check whether the angle code of the adjacent two plates is staggered. The test assembly shall be carried out to check its levelness and verticality, and then the test shall be assembled with stainless steel bolts. The test shall be fixed on the main and auxiliary keels. The horizontal and vertical seam clearance shall be adjusted to meet the requirements.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Honeycomb aluminum sheet is a new composite material with sandwich structure, which is composed of upper and lower aluminum sheets and aluminum honeycomb core through adhesive. The panel of honeycomb aluminum plate is usually sprayed with fluorocarbon coating or polyester coating. The fluorocarbon coating is widely used outdoors because of its good weather resistance and self-cleaning, and the polyester coating is mostly used indoors.

Recommended:How about the performance of the lock solid wood composite floor