China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

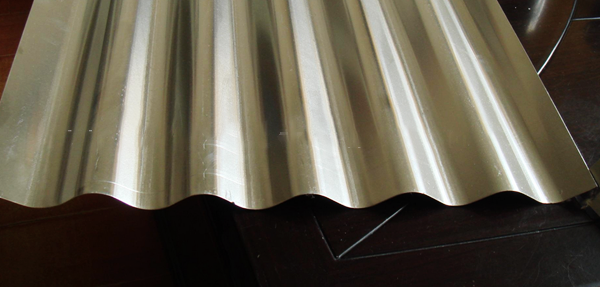

perforated aluminum corrugated boardAlso known as pressure aluminum plate, wave aluminum plate or aluminum tile. It is one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

Second: aluminum has a good antirust effect, in the outside environment, rain, sun exposure, snow for aluminum almost no damage, and like iron, see the rain after the rapid rust, from the above two points can be seen, aluminum tile to a large extent can completely replace the stainless steel material, at the same time lower cost, is the preferred material for the construction industry.

Punched aluminum corrugated board is a new type of composite aluminum curtain wall material. It is formed by bonding the corrugated core board with a panel 0.6-0.8mm bottom plate of 0.4mm and a middle 0.2mm corrugated core board. The surface of the corrugated core board is coated with a thermosetting epoxy resin adhesive and heated and pressurized. The composite method is similar to that of corrugated cardboard box board.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The advantages of punching aluminum corrugated board are energy-saving: aluminum corrugated board is light in weight, and its weight of 4.3kg per square is only equivalent to 50% of aluminum veneer.

Disadvantages of punched aluminum corrugated board The structure of aluminum corrugated board is generally three layers, with 0.4-0.8 thick aluminum layers on both sides of the outside. The corrugated core material in the middle is 0.2-0.4 and bonded with thermosetting epoxy resin adhesive. The product quality is greatly affected by the stability of glue and the temperature of the workshop during production and processing, poor control of the production process will cause the top plate and bottom plate with corrugated core material adhesion and degree is not strong, resulting in deformation and fall off, affecting its overall production, installation quality.

stainless steel honeycomb plateEasy and fast installation.

The quality of the panel is the key to the whole processing process. When the ductility of the panel aluminum material is not high and the thickness is too thin, the panel is easy to break when the curved surface is bent. Therefore, the panel should not be aluminum plate with a thickness of less than 0.8mm, and the material should be the national standard 3003H24 aluminum alloy coil.

Recommended:What are the product advantages of PVC composite gusset