China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

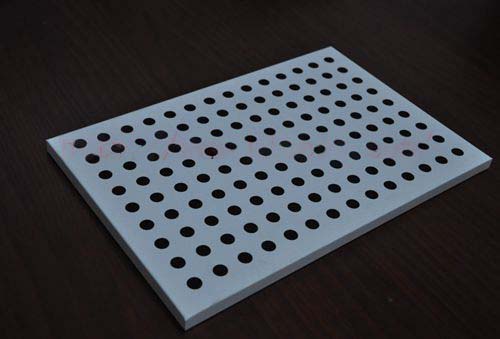

Honeycomb aluminum plate shapeThe product series has the advantages of excellent material selection, advanced technology and reasonable structure. It not only has excellent performance in large scale and flatness, but also has many choices in shape, surface treatment, color, installation system and so on.

In addition, the panel in addition to the use of aluminum alloy, but also according to customer needs to choose other materials, such as: copper, zinc, stainless steel, pure titanium, fire board, Zhong Qian board, marble, aluminum-plastic board and so on. Honeycomb aluminum plate is a series of metal composite panel Products developed in combination with the aviation industry composite honeycomb panel technology.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

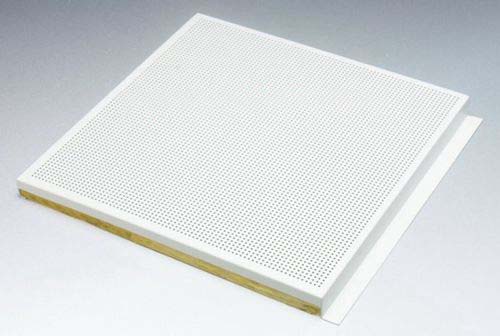

Honeycomb aluminum plate molding Products adopt honeycomb sandwich structure, that is, high-strength alloy aluminum plate coated with excellent weather resistance decorative coating is used as the surface, and the bottom plate and aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Construction technology of honeycomb aluminum plate: honeycomb aluminum plate is a series of metal composite plate Products developed in combination with the technology of composite honeycomb plate in aviation industry. The product uses a honeycomb sandwich structure, that is, a high-strength alloy aluminum plate with a decorative coating with excellent weather resistance is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

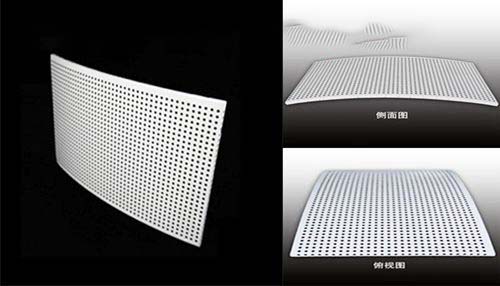

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

The installation of aluminum plate is carried out on the basis of keel leveling. It is installed successively from the middle to one direction according to the aluminum plate control line, and is fixed to the keel skeleton by fasteners matching the ceiling.

The contact surface between the aluminum plate panel and the steel keel is isolated by insulating sheet to prevent electrochemical corrosion. After the installation of large area aluminum plate, due to the change of weight, the deflection of keel will change again, resulting in the error of local flatness of the panel. After the deformation is stable, the aluminum plate is leveled to digest the effect of keel deformation on the flatness of the panel.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

Honeycomb aluminum panel modeling is a series of metal composite panel Products developed in combination with composite honeycomb panel technology in the aviation industry. The honeycomb aluminum plate adopts the honeycomb sandwich structure, that is, the high-strength alloy aluminum plate with excellent weather resistance and decorative coating on the surface is used as the surface, and the bottom plate and the aluminum honeycomb core are made of composite plates under high temperature and high pressure.

Recommended:What are the product advantages of aluminum-plastic composite gusset plate