China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

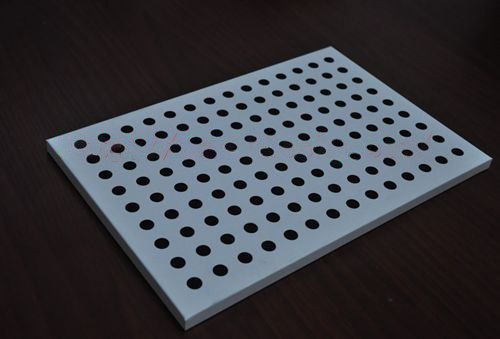

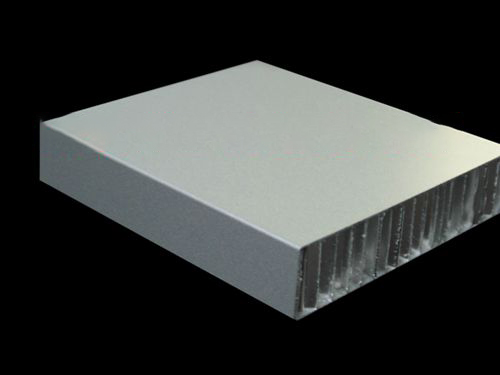

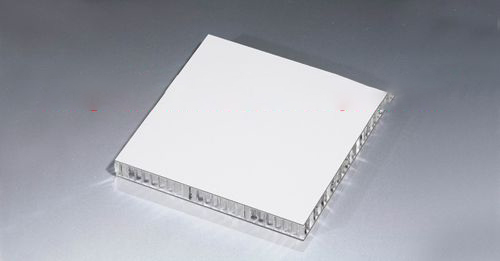

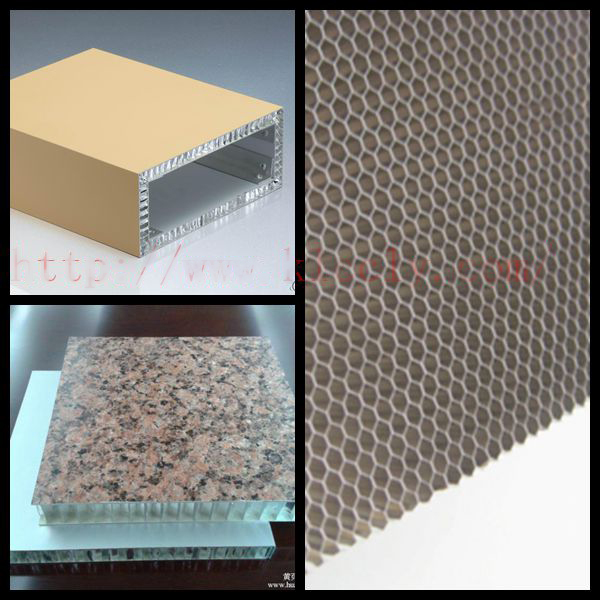

The structural structure of punched sound-absorbing honeycomb aluminum plate is perforated panel and perforated back plate, which are directly bonded to aluminum honeycomb core by high-quality adhesive to form aluminum honeycomb sandwich structure, and a layer of sound-absorbing cloth is pasted between the honeycomb core and the panel and back plate.

Read more

The solid wood composite floor lock is made of plates of different tree species, which overcomes the shortcomings of wet expansion and dry contraction of solid wood floor to a certain extent. The dry shrinkage and wet expansion rate is small, has good dimensional stability, and retains the natural wood grain and comfortable foot feeling of solid wood floor. Solid wood composite flooring both the stability of the laminate flooring and the aesthetics of solid wood flooring, but also has the advantage of environmental protection.

Read more

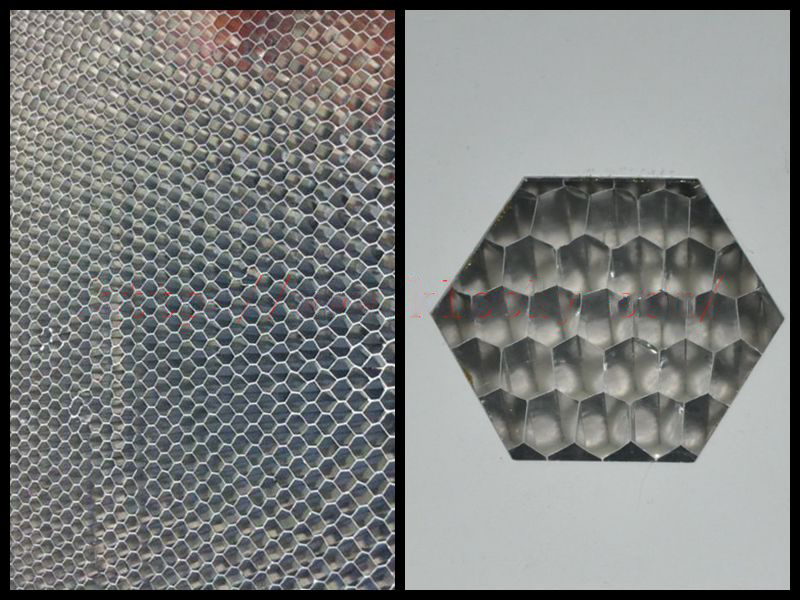

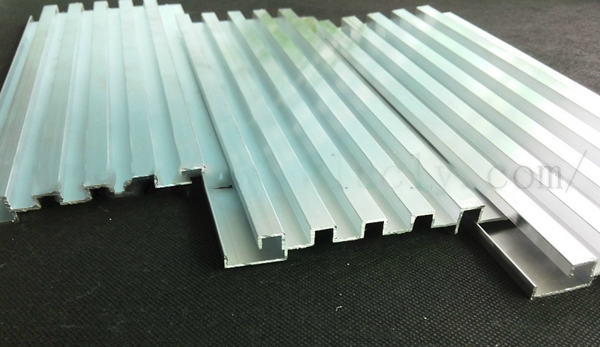

High-speed aluminum honeycomb panels provide architects with a wealth of choices from panel material, shape, installation system to color, and surface treatment. They can show rich smallpox performance effects and have excellent design freedom.

Read more

Galvanized zinc corrugated plate is composed of aluminum-zinc alloy structure, composed of 55% aluminum, 43% zinc and 2% silicon solidified at 600 ℃, the whole structure of aluminum-iron-silicon-zinc, forming a dense quaternary crystal of an alloy.

Read more

The core of the composite honeycomb aluminum plate manufacturer is divided into many closed cells, which prevents the air flow, hinders the sound wave, improves the sound absorption coefficient (up to 0.9 or more), and improves the strength of the plate itself,

Read more

Aluminum corrugated board specifications are one of the commonly used Products in construction, and there is a trend to replace stainless steel and iron plates. First of all, because the density of aluminum is only 2.71 and the density of iron is 7.8, the weight of each square aluminum tile is less than 1/3 of that of stainless steel, which can reduce the cost of the enterprise and reduce the pressure of the bracket.

Read more