China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Technical requirements for aluminum honeycomb composite panels for building exterior walls[aluminum honeycomb panel外墙基本标准如下][1.范围]本标准适用于HDAPC生产的建筑外墙用铝蜂窝复合板。[2.规范性应用文件]GB/T 1958 形状和位置公差检测规定GB11339-8 直线度和平面度误差检测GB1958 直线度和平面度GB/T 191 包装储运图示标志GB/T 6388 运输包装收发货标志GB/T 3199 铝及铝合金加工产品包装、标志、运输、储存GB/T 1452-2005 夹层结构平拉强度试验方法GB/T 1453-2005 夹层结构或芯子平压性能试验方法 GB/T 1455-2005 夹层结构或芯子剪切性能试验方法GB/T 1456

Read more

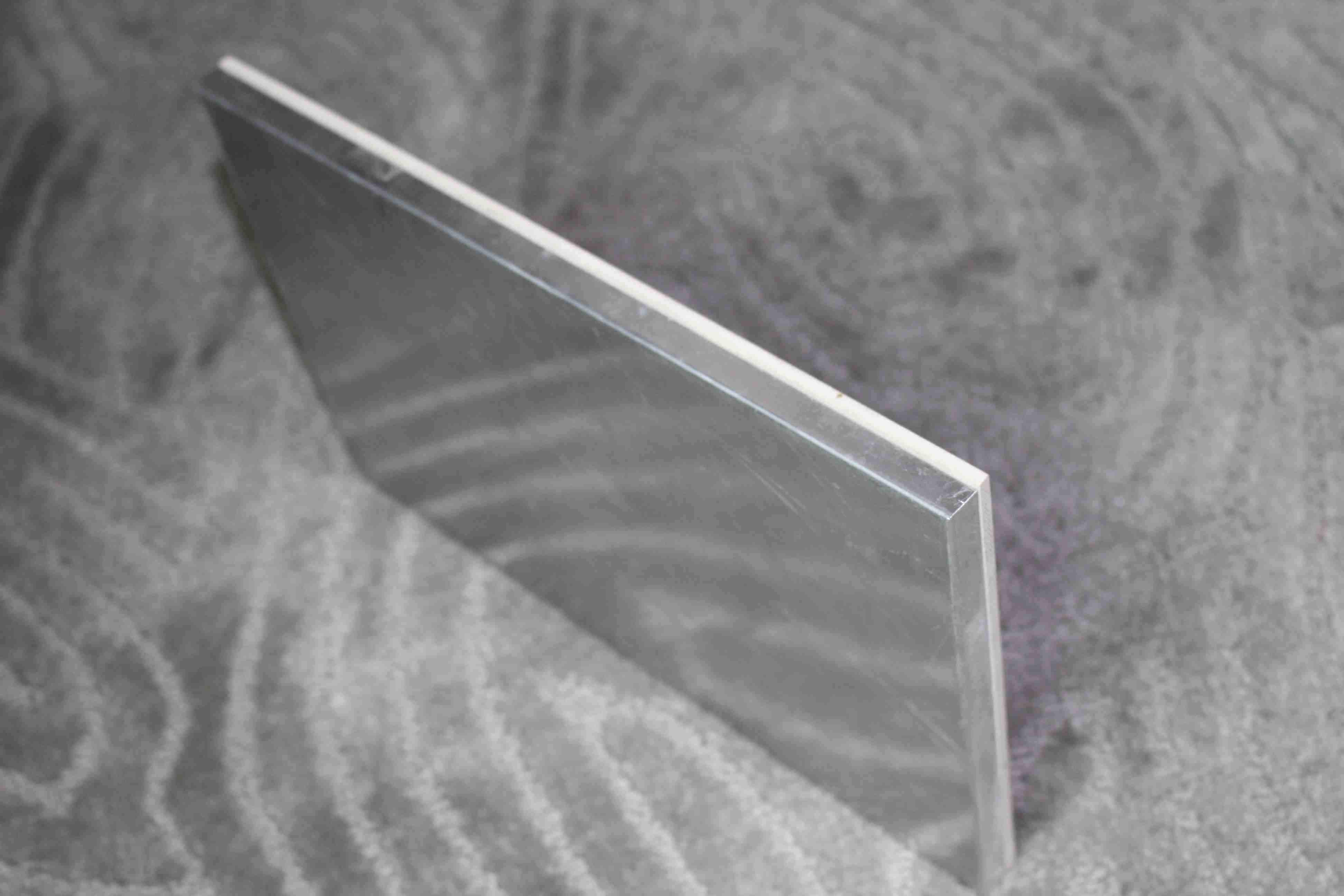

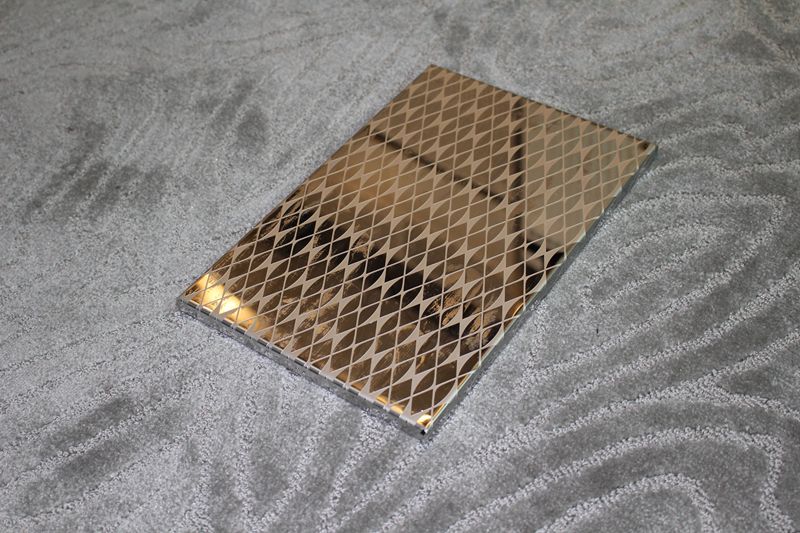

1. sound insulation, heat insulation, fire prevention and shockproof functions can be highlighted because the core board is corrugated arc type, which produces curved reflection on sound waves, eliminates the sound wave coupling between the panel and the back plate, and improves the sound insulation performance by more than 35dB. The 2. has light specific gravity, high strength, high rigidity, stable structure and good wind pressure resistance. Due to the thickness of the aluminum panel is 0.7mm, the carrying capacity of the aluminum corrugated composite panel is small after folding, so it is not suitable for large plate or large height curtain wall project. Due to the linear expansion coefficient of 2.35x 10-5, the aluminum veneer has a large deformation due to cold shrinkage and thermal expansion. Generally, the surface of the aluminum plate will have concave-convex deformation after 1-2 years of use, which will affect the artistry of the building facade. The flatness of the outer s

Read more

The installation method is to separate the lifting lug and the honeycomb plate. After the lifting lug is processed separately, it is connected to the glue seam position of the honeycomb plate. The suitable width of the glue seam is ≥ 12mm. The correct installation method of the honeycomb aluminum plate makes the processing simple and convenient.

Read more

The honeycomb aluminum plate curtain wall of the Project is installed with 12mm thick U-shaped box-type honeycomb aluminum plate decorative strip and new type mother-child buckle connecting fastener.

Read more

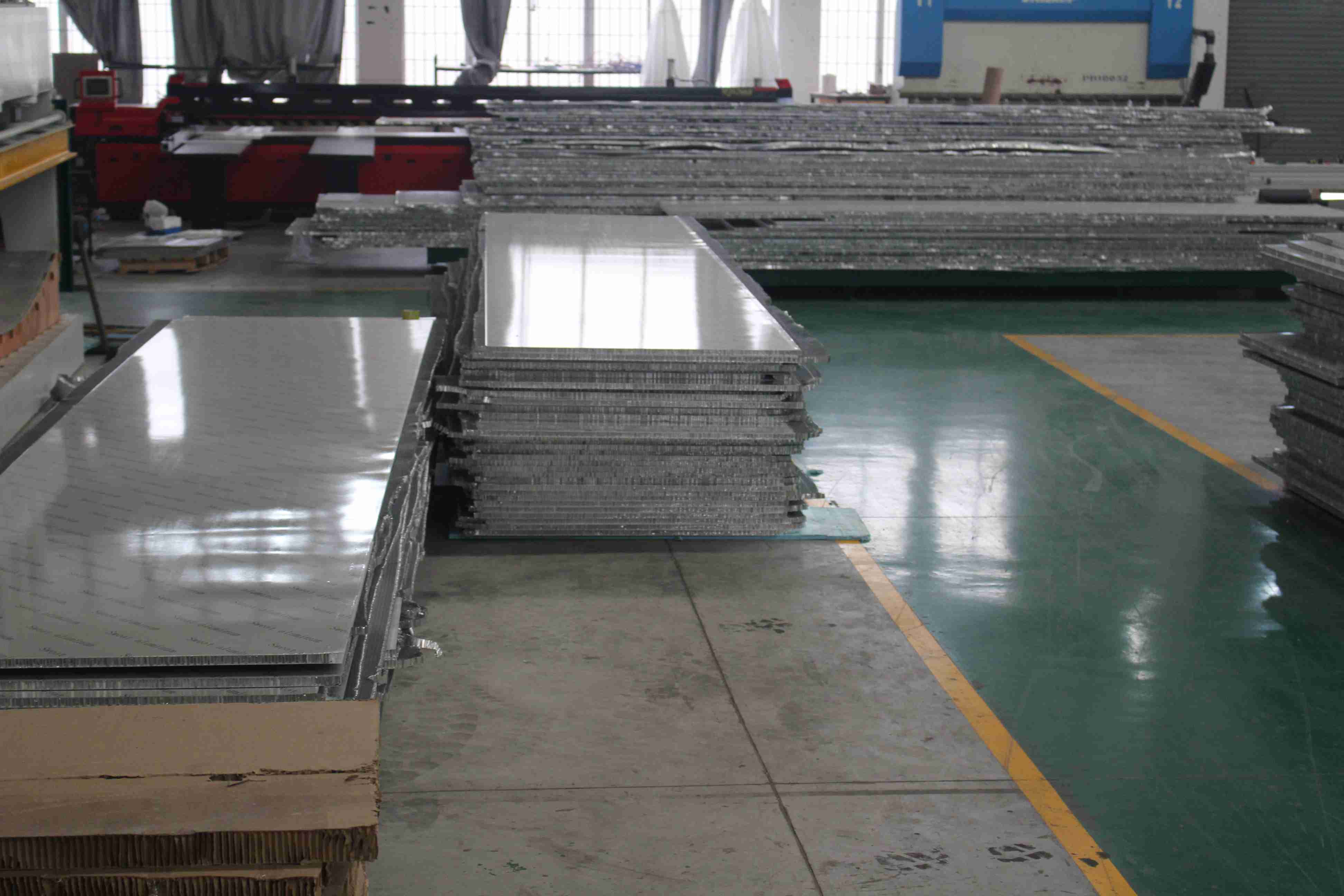

The production cycle of honeycomb aluminum plate Honeycomb aluminum plate, also known as aluminum honeycomb plate, is the preferred decorative material for designers in the market at present. Aluminum honeycomb plate is a special customized product. Many people will care about its production cycle and whether it will affect the construction period. Today, I will talk to you about this topic. First of all, I would like to talk about several factors that affect the production progress of aluminum honeycomb panels: ① specifications (if there are too many specifications, the production cycle will be seriously affected); ② whether punching is required (if the surface of aluminum honeycomb panels needs punching, especially micropores, this will be very slow); ③ surface treatment (normal aluminum honeycomb panels are usually coated with pre-rollers, if special colors are sprayed, such: wood grain, stone grain, etc. will seriously affect the production progress) ④ plate shape (such as arc, curved surface production progress will be greatly reduced) some professional production of aluminum honeycomb panel of large manufacturers of general daily output is as follows: ① 1-3 specifications of flat plates (surface pre-roller coating) can produce about 2000 square meters a day without folding ② 1-3 specifications of flat plates (surface pre-roller coating) can produce about 1000 square meters a day with folding ③ arc shape

Read more

Teach you how to choose aluminum honeycomb panel manufacturers, choose a good product.

Read more