China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Aluminum honeycomb panel manufacturing technology from the aviation industry. The product selection of the company's unified standard pre-roller coated high-grade aluminum alloy coil, combined with a variety of production processes refined.

Read more

The aluminum honeycomb panel is made of polyurethane and epoxy resin room temperature curing adhesive, and its bonding strength is low. For the honeycomb core, the side length is 4mm and the panel thickness is 1mm.

Read more

First of all, the aluminum honeycomb panel is mainly made of composite honeycomb structure, and also uses high-quality alloy plate to make, and aluminum honeycomb panel can also show people a rich roof performance effect, therefore, has excellent design freedom.

Read more

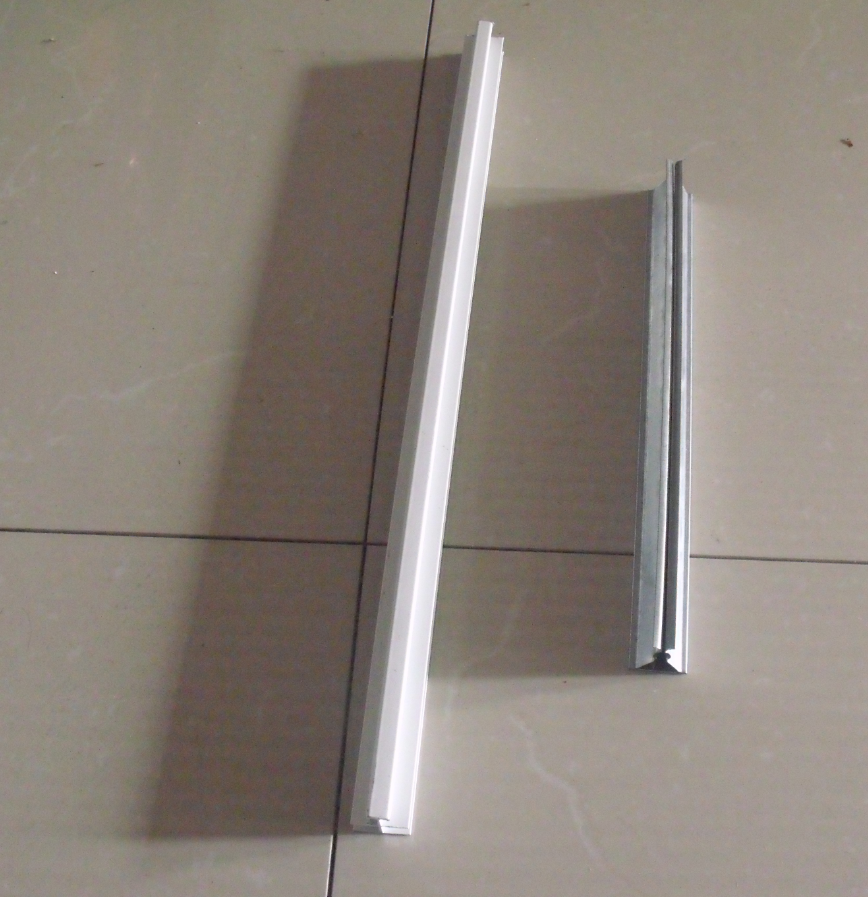

Honeycomb aluminum sheet is a new composite material with sandwich structure, which is composed of upper and lower aluminum sheets and aluminum honeycomb core through adhesive. The panel of honeycomb aluminum plate is usually sprayed with fluorocarbon coating or polyester coating. The fluorocarbon coating is widely used outdoors because of its good weather resistance and self-cleaning, and the polyester coating is mostly used indoors.

Read more

The double-layer metal roof system effectively combines the honeycomb aluminum plate and the aluminum-magnesium-manganese vertical lock-edge roof system into a whole, and uses the special node structure of the vertical lock-edge plate rib to separate the honeycomb plate.

Read more

For the indoor aluminum honeycomb panel curtain wall decoration with single curved surface modeling, how to solve the disadvantages of the traditional aluminum plate processing and aluminum plate installation in the past, so as to make good use of the advantages and avoid the disadvantages? At present, the more popular and fashionable decoration hanging process is to use the mold to form the aluminum honeycomb panel.

Read more