China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

According to the composite skills of honeycomb aluminum plate from the scientific and technological achievements of modern aviation, the weight is lighter, but the strength of the plate is higher. Use high temperature composite and panel hot pressing skills to ensure the integrity, strength and flatness of the board.

Read more

In recent years, in addition to the home in the coffee table also began to use honeycomb aluminum, many people have noticed that the IKEA bookcase also appeared in the figure of honeycomb aluminum, this new type of environmental protection and energy saving materials favored by large enterprises.

Read more

The aluminum honeycomb panel is a honeycomb sandwich panel with a honeycomb structure as the core layer, which is inspired by the natural hexagonal honeycomb. Aluminum honeycomb panels made of aluminum alloy are not only the lightest in other materials of the same volume due to their unique structure.

Read more

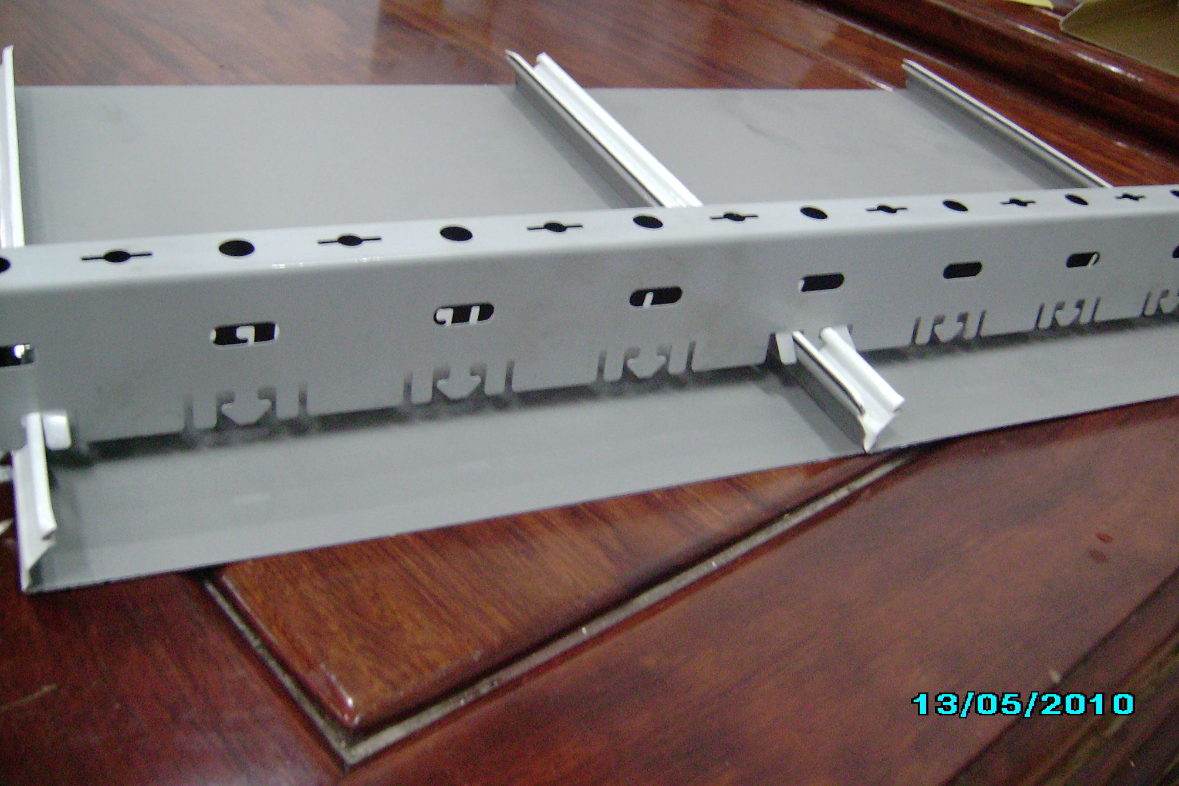

Honeycomb aluminum plate generally uses pure aluminum plate, aluminum plate thickness is 3mm, but in order to reduce the weight of aluminum plate, improve the strength of aluminum plate, now more use of aluminum alloy plate, usually choose No. 21 antirust aluminum (code LF21) rolled aluminum plate

Read more

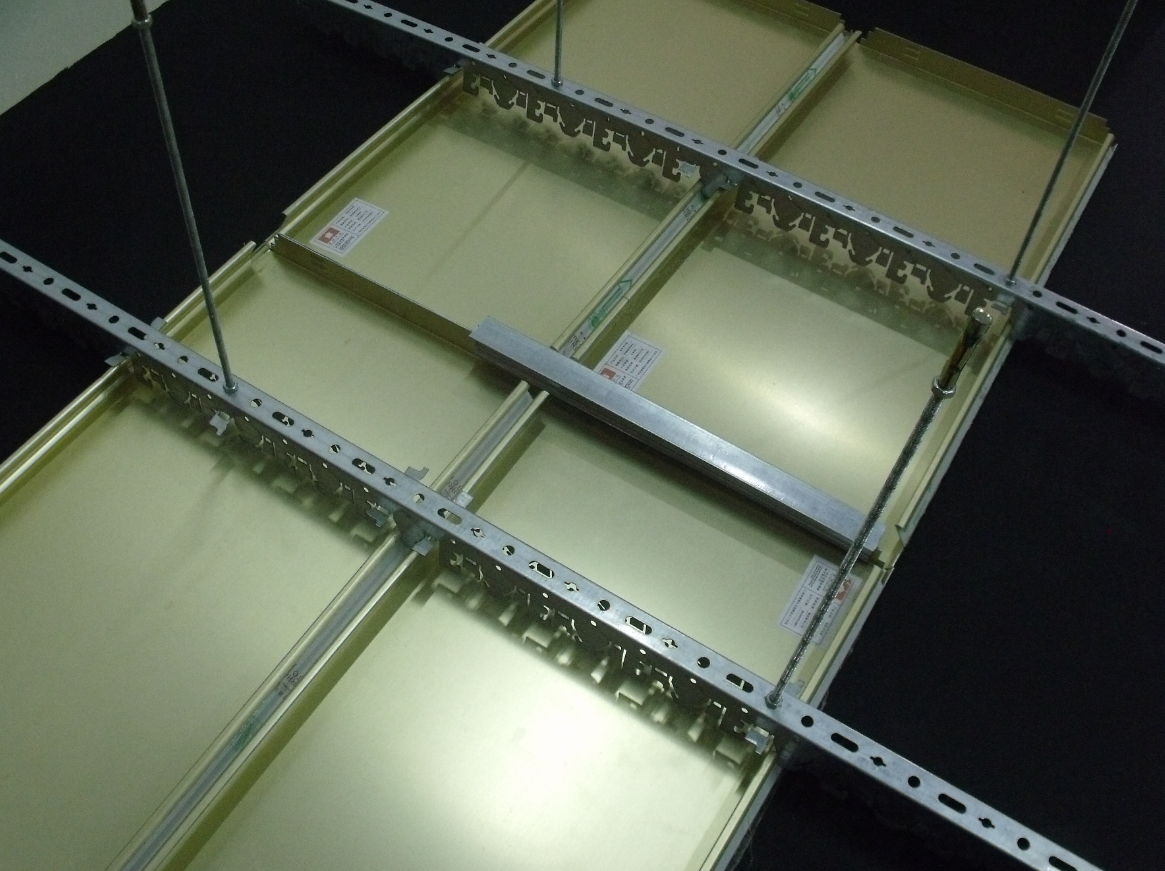

The honeycomb aluminum plate double-layer metal roof system effectively combines the honeycomb plate and the aluminum magnesium manganese vertical lock edge roof system into a whole, using the vertical lock edge plate rib special node structure.

Read more

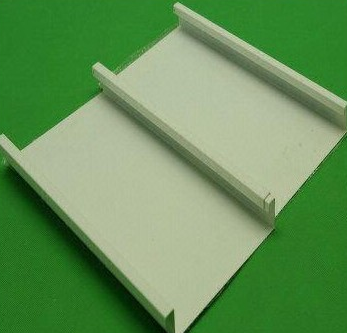

Aluminum honeycomb panel is a high-grade aluminum alloy panel, back plate and aluminum honeycomb core material hot pressing composite molding of large surface composite materials, product specifications are diverse, the surface can be embossed, mirror, relief, drawing, electroplating, anodizing, matte, bright light and metal color and other treatments, to meet the application needs of a variety of places.

Read more