China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

The surface of the front aluminum plate of the modeling aluminum honeycomb panel manufacturer is coated with fluorocarbon baking varnish conforming to AAMA and ECCA standards. The color selection is the same as that of the aluminum-plastic composite panel, providing a wide range of standard colors, including plain colors and metallic colors, and can also be specified by the customer.

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The surface of honeycomb board for outdoor construction is made of fluorocarbon (PVDF) roller coating, baking varnish or ceramic coating, which has excellent weather resistance, ultraviolet resistance, moisture resistance, pollution resistance and other properties. At the same time, titanium zinc plate, copper old plate can also be used for honeycomb plate surface material.

Modeling aluminum honeycomb panel features:

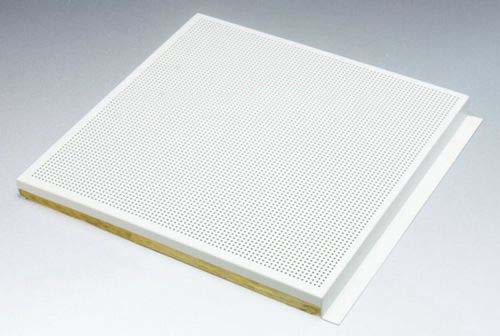

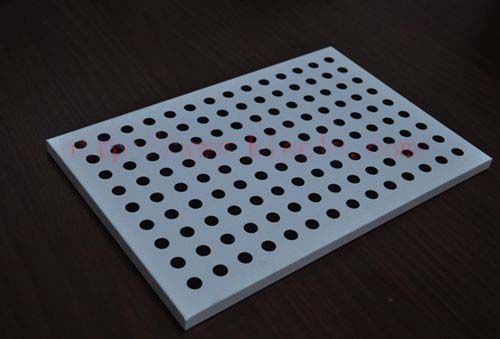

1, The center is aluminum hexagonal honeycomb with low density (about 3~7kg per square meter). The manufacturer of aluminum honeycomb panel is 1/5 of the weight of wood with the same thickness and area, 1/6 of glass and 1/7 of aluminum, greatly reducing the construction load and cost.

2, Because the middle interlayer contains a large amount of air, it can make sound insulation (air sound insulation can reach 30dB), heat insulation (thermal resistance can reach 0.02(㎡?K/W)), no combustible substances, fire rating can reach B1 level, waterproof, moisture-proof, no harmful gas release, high specific strength per unit mass, high specific rigidity (structural rigidity is 1.7 times of rib type), and not easy to deform.

Stone Honeycomb PanelScope of application: all kinds of large public building channels, airports, exhibition halls, shopping centers, stations, Tunnel corridors, etc.

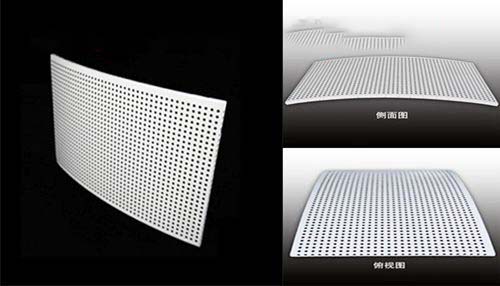

3, completely overcome the deformation of other decorative panels in a single large area, modeling aluminum honeycomb panel manufacturers in the middle of the collapse and other shortcomings of convenient processing and application, can be arbitrarily cut folding, surface fluorocarbon coating can guarantee product life of more than 30 years.

4. The surface of aluminum honeycomb panel has extremely high flatness and good seismic performance, which is only 1/8 of the proportion of glass curtain wall. The load of 22mm thick standard parts can reach more than 700kg force when it is simply supported at 1 meter and the deflection is 10mm.

stainless steel honeycomb plateEasy and fast installation.

The honeycomb aluminum panel wall panel system is based on the composite honeycomb panel technology developed by the aviation industry. Such advanced technology enables the company to manufacture wall panel Products with good strength and light weight. These wallboard Products have a very flat surface and the width of the joints can be strictly controlled, which allows the architect to design a very flat and beautiful wall with a large surface.

Recommended:What are the uses of honeycomb aluminum plate