China's earliest production and processing of aluminum veneer ceiling, one of the curtain wall manufacturers

Corrugated alloy aluminum plateUnique texture, rich color, excellent plasticity, form diversity, weather resistance and are favored by designers. In modern buildings, its utilization rate is more and more sought after by people, which is a leap in building decoration. The installation of exterior decorative panels in the form of aluminum plate curtain wall can be used in high-rise buildings of any building, any height, any part and any structural form, in this way, it breaks the restriction that high-rise buildings and super high-rise buildings cannot use certain decorative panels for exterior decoration.

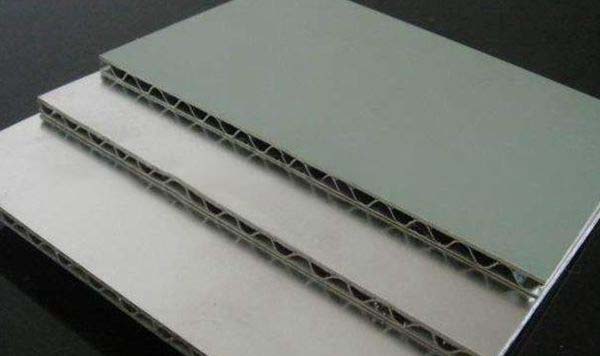

aluminum corrugated boardIs the use of aluminum after rolling cold bending into a variety of waveform plate, it is suitable for industrial and civil buildings, warehouses and interior and exterior wall decoration, with light weight, high strength, fire prevention, long life and other characteristics, has been widely applied.

The specific cleaning steps of corrugated alloy aluminum plate are as follows:

1. Rinse the surface of the board with plenty of water first;

2. Use a soft cloth soaked in water-diluted detergent to gently wipe the test panel;

3. Rinse the board surface with plenty of water to wash away the dirt;

4, check the board surface, for not clean the place with detergent focus on cleaning;

5. Rinse the board surface with clean water until the detergent is completely washed away.

arc honeycomb panelFeatures: sound insulation, heat insulation, fire prevention, shockproof function outstanding.

Casting: Casting is the first process of aluminum production. The main process is:

(1) Ingredients: According to the specific alloy grades to be produced, calculate the addition amount of various alloy components, and reasonably match various raw materials.

(2) smelting: the prepared raw materials are added into the smelting furnace to melt according to the process requirements, and the slag and gas in the melt are effectively removed by degassing and slag removal refining means.

stainless steel honeycomb plateEasy and fast installation.

(3) Casting: Under certain casting process conditions, the molten aluminum liquid is cooled and cast into round casting rods of various specifications through the deep well casting system.

Testing of Transverse Tensile Strength of Thermal Insulation Broken Bridge Profiles: Transverse Tensile Strength Attempt to Lag in Shear Failure G Disclosure. The shear force fails after 2mm displacement flashes between the inner and outer aluminum alloy profiles. After the process of transverse tensile strength detector economic situation downturn.

Recommended:The scope of application of 750 corrugated aluminum sheet